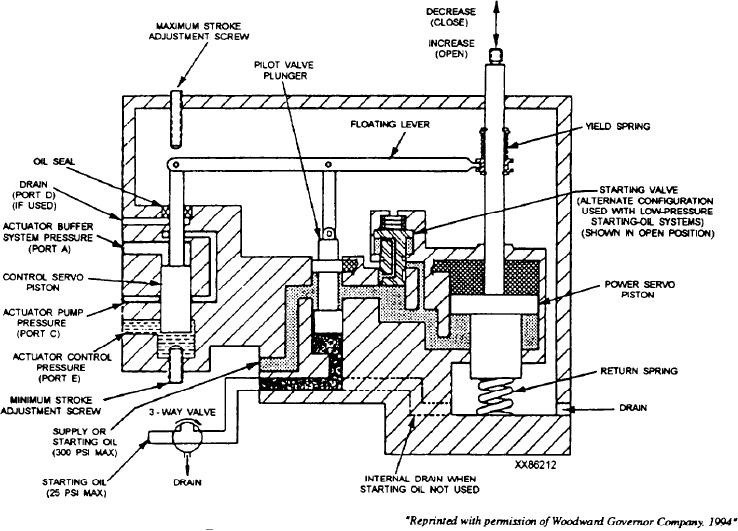

high-pressure lines. The control servo piston, which is

2. Port C- Actuator pump output pressure is

an integral part of the amplifier, is used in place of the

connected to annular seal grooves in the control

remote servo piston to control the movement of the

piston and piston rod bores, ensuring that any oil

hydraulic amplifier pilot valve plunger.

leakage comes from a part of the hydraulic

circuit where it does not adversely affect control

The use of a three-way valve, a starting valve, and

a yield spring are necessary starting aids. These will be

pressure or oil flow.

discussed later.

3. Port E- Actuator control pressure tends to move

The hydraulic amplifier does not have its own oil

the control servo piston upward (increase fuel or

pump. Consequently, operating oil pressure and supply

steam).

must come from an external source (usually the prime

Pressure in the compensation or buffer port (port A)

mover lubricating system). The use of a starting oil

and the control port (port E) are constant at steady state

pump is necessary when the prime mover is being

for all control servo positions. Control oil pressure at

started. Once the prime mover develops its own

port E is approximately one-half the compensation oil

pressure, this pump is secured.

pressure at port A. The control oil pressure varies much

Refer to figure 9-5 for a schematic diagram of the

more than the compensation oil pressure during a

hydraulic amplifier. The control ports are connected to

transient. The variations in control oil pressure causes

correspondingly identified ports in the EG-R actuator

the control piston to move.

(fig. 9-4). Oil at these ports perform the following:

The control servo piston is connected to one end of

1. Port A- Actuator buffer compensation system

a floating lever in the amplifier. Any change in position

pressure always tends to move the amplifier

of the control piston is transmitted to the floating lever.

control servo piston downward (decrease fuel or

The movement of the floating lever is transmitted to the

steam).

Figure 9-5.--Hydraulic amplifier schematic diagram.

9-8