COMMUTATORS AND COLLECTOR

RINGS (SLIP RINGS)

After being used about 2 weeks, the commutator of

a machine should develop a uniform, glazed,

dark-brown color on the places where the brushes ride.

If a nonuniform or bluish-colored surface appears,

improper commutation conditions are indicated.

Periodic inspections and proper cleaning practices will

keep commutator and collector-ring troubles at a

minimum.

CLEANING COMMUTATORS AND

COLLECTOR RINGS

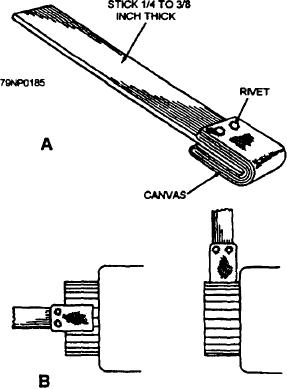

One of the most effective ways of cleaning the

commutator or collector rings is to apply a canvas wiper

while the machine is running. You can make the wiper

by wrapping several layers of closely woven canvas

over the end of a strong stick between one-fourth and

three-eighths inch thick (fig. 7-15, view A). Secure the

canvas with rivets, and wrap linen tape over the rivets

to prevent the possibility of them coming in contact with

Figure 7-15.--Cleaning commutator or collector rings.

the commutator. When the outer layer of canvas

becomes worn or dirty, remove it to expose a clean layer.

paper, or emery stone on a commutator or collector ring

The wiper is most effective when it is used frequently.

since the danger of causing electrical shorts exists.

On ship's service generators, it may be desirable to use

the wiper once each watch. When using the wiper,

TRUING COMMUTATORS AND

exercise care to keep from fouling moving parts of the

COLLECTOR RINGS

machine. The manner of applying the wiper to a

commutator is illustrated in figure 7-15, view B.

With proper care and maintenance, commutators

and collector rings can be counted on to provide years

When the machines are secured, you can use a

of carefree service. If not maintained properly,

toothbrush to clean out commutator slots. You can use

commutators and collector rings may be subject to any

a clean canvas or lint-free cloth for wiping the

number of problems including excessive threading,

commutator and adjacent parts. Besides cleaning by

grooving, copper drag, excessive out-of-roundness,

wiping, periodically clean the commutator with a

waviness, high bars, high mica, slot or pitch patterns,

vacuum cleaner or blow it out with clean, dry air.

contaminated surface films, and so forth.

Do not sandpaper a commutator if it is operating

When any of these symptoms is encountered, the

well, even if long service has developed threading,

most efficient and economical course of action usually

grooving, pits, burn areas between bars, longitudinal

is to begin corrective maintenance immediate y, rather

irregularities, etc., unless sparking is occurring or the

than wait for the condition to get worse. It is desirable,

brushes are wearing excessively. In sanding a

however, to know the history of the machine before

commutator, use a fine grade of sandpaper (No. 0000 is

performing corrective maintenance. For example, light

preferred, but in no case coarser than No. 00). You can

use sandpapering to make emergency reduction of high

threading, small pits, longitudinal irregularities or wide

mica or to polish finish a commutator that has been

slots between bars made during undercutting usually

indicate a need to resurface a commutator or collector

stoned or turned. The sandpaper, attached to a wooden

ring in place. However, if there is no sparking, brush

block shaped to fit the curvature of the commutator, is

wear is normal, and these abnormalities have developed

moved slowly back and forth across the surface of the

over along period of time, no corrective action need be

commutator while the machine is running at moderate

taken. Often, the best maintenance is to leave a well

speed. Rapid movement or the use of coarse sandpaper

running machine alone.

will cause scratches. Never use emery cloth, emery

7-13