Sandpapering will not correct flat spots, grooves,

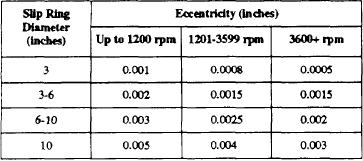

Collector Ring Circularity

eccentricity, or out-of-roundness condition You can

correct some or all of these conditions by machine

The maximum total indicated runout (TIR) for

stoning or handstoning, by turning on a lathe, or by

collector rings is normally 0.001 inch to 0.002 inch. See

grinding with a rigidly supported stationary or revolving

table 7-3 for eccentricity limits for various collector ring

stone. There are a number of grades of commutator

diameters. Collector ring diameters are typically small

stones, from coarse to very fine, that cart be used for

in comparison to commutators, and surface

handstoning or grinding. Use the finest stone that will

irregularities accentuate brush motion more. Larger

do the job in a reasonable time. Do not use coarse

commutators (18 inches in diameters) have

stones, as they tend to produce scratches that are hard to

surface/brush interfacing that often allow excessive

remove. In turning or grinding commutators and

out-of-roundness conditions without catastrophic

collector rings, it is essential that the cut be parallel with

failure.

the axis of the machine; otherwise, a taper will result.

Commutator Circularity

Do not disturb the commutator clamping bolts

unless the bars are loose (one or more high bars). Then

Ideally, commutator surfaces should be smooth and

use a calibrated torque wrench and tighten only to the

mechanically true. Optimum perfomance is obtained

values specified by the manufacturer's instruction

if maximum runout of a commutator surface with

manual for motors and generators. Make all other

respect to its center of rotation does not exceed 0.002

needed repairs, such as balancing, rebrazing armature

inches. This value is a judgment criterion and is

connections, and repairing insulation faults, before

dependent upon the type of irregularity. Maximum

truing the commutator.

allowable runout criteria could vary from less than 0.002

After the commutator is trued (whether by stoning,

inches for wavy commutator surfaces to 0.005 inches

grinding, or turning), finish with a fine grade of stone or

for elliptical surfaces. The type of irregularity and also

sandpaper, undercut the mica, chamfer the commutator

the degree of brush shunt fraying must be taken into

bars (to be explained later in this chapter), clean the

consideration when evaluating the commutator surface

commutator and brush holders, and wipe off the brushes

condition.

with a clean, dry, lint-free cloth.

Corrective Action

HANDSTONING.-- Handstoning will remove flat

spots, grooves, scoring, and deep scratches; but, it will

Do not hue a commutator or collector ring in place

not correct eccentricity, high bars, or an out-of-round

unless its condition has become so bad that it cannot wait

condition. The machine should be running at, or slightly

until the next shop overhaul for reconditioning. Large

below, the rated speed. Generators can normally be

turned by their prime movers; however, some

commutators in the 125- to 850-rpm range, used on most

electric propulsion motors and generators, usually

generators and motors must be turned by a pneumatic

operate satisfactorily with runouts up to 0.003 inch.

or other prime mover.

Under no condition should you attempt to true a

The stone should be formed or worn to the curvature

commutator or collector ring in place unless there is

of the commutator and should have a surface much

sparking, excessive brush wear, or brush movement

larger than the largest flat spot being removed. Hold the

sufficient to fray the brush pigtails and wear the hammer

stone in the hand and move it very slowly back and forth,

plates. Do not confuse brush chatter with brush

parallel to the axis of the surface. Do not press too hard

movement by runout.

on the stone, just enough to keep it cutting. Being hasty

Table 7-3.--Collector Ring Eccentricity Limits

or crowding the stone results in a rough surface and

possibly an out-of-round condition. Avoid jamming the

stone between the fixed and moving parts of the

machine.

MACHINE STONING.-- Stoning should be done

by machine to correct eccentricity, high bars, or an

out-of-round condition. In one method of machine

stoning, a commutator dressing stone tool (fig. 7-16) is

mounted on the frame of the machine and holds a

7-14