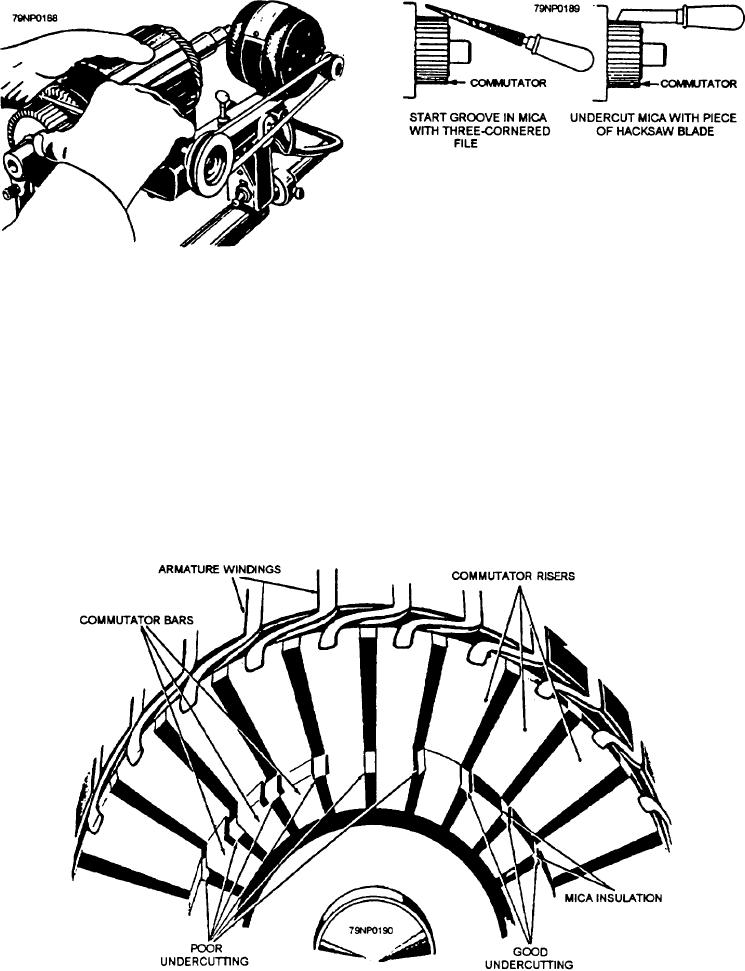

Figure 7-19.--Undercutting mica with a hacksaw blade.

If a mica undercutter is not available, use hand tools

to cut the mica, as shown in figure 7-19. Do not use a

lubricant. Also, do not widen the commutator slots by

removing metal from the bars, nor leave a thin edge of

Figure 7-18.--Undercutting commutator mica with

mica next to the bars.

undercutter.

After removing the high mica, smooth off all burrs.

The rotary cutters are either U- or V-shaped. The

Then polish the commutator and test. Figure 7-20 shows

U-slots will give long wear and are best suited to

examples of good and poor undercutting.

slow-speed machines or machines that operate in a clean

atmosphere and require little maintenance. The V-slots,

DISASSEMBLY AND REASSEMBLY

which are more quiet than U-slots, are better if dirt and

OF ROTATING ELECTRICAL

dust are present. The proper thickness for a U-shaped

MACHINERY

cutter is equal to the thickness of 0.001 inch. In

When you have to disassemble and reassemble a

general, it is best not to cut U-shaped slots deeper than

large motor or generator, follow the procedures outlined

one thirty-second of an inch, or, at most, three

in the manufacturer's instruction manual, exercising

sixty-fourths of an inch. The V-shaped slots are cut to a

care to prevent damage to any part of the machine. The

depth that will remove some copper at the top.

Figure 7-20.--Example of good and poor undercutting.

7-17