If you have done a careful job of breaking down a

machine into its components, the process of reassembly

should be the reverse order of disassembly.

A few simple steps are to be taken when

disassembling a motor or generator:

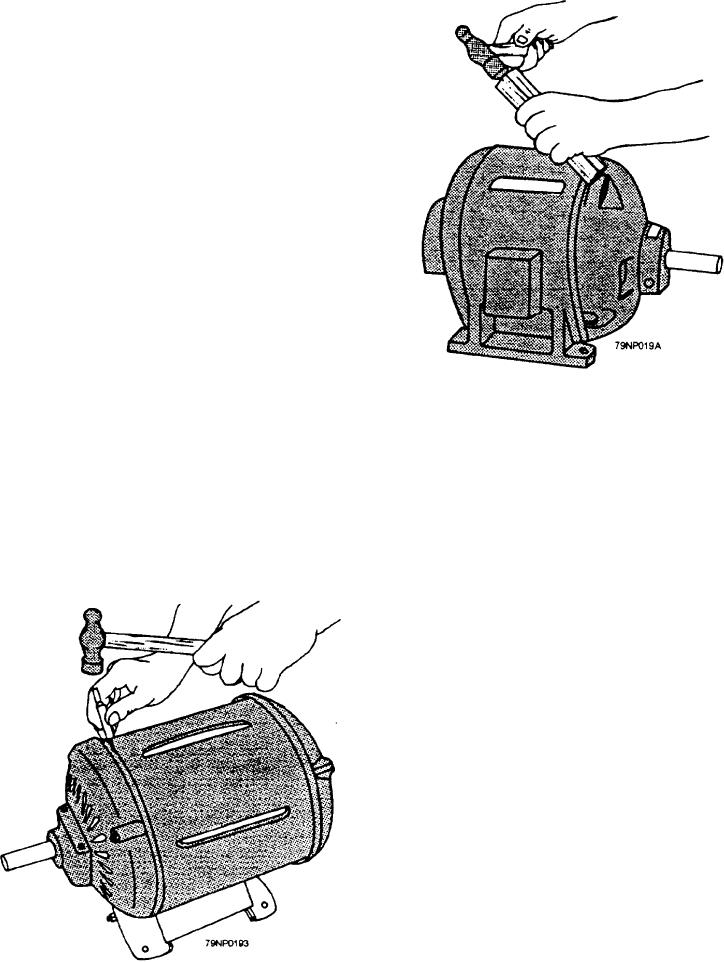

1. Make sure you mark the frame and mating end

bells (fig. 7-23), using a different mark for each

end

2. When separating the end bells from the frame,

use a mallet or block of wood with a hammer

(fig. 7-24). Never pry mating surfaces apart with

a metal object such as a screwdriver.

3. To prevent damaging the brushes, lift them from

the commutator and/or slip rings before

removing the rotor.

4. Protect the windings by inserting thin strips of

waxed paper between the rotor and stator.

Figure 7-24.--Parting end bells with a hammer and a wood

5. When using an arbor press to remove bearings,

block.

take the proper precautions. (Place a pair of flat,

steel blocks under the inner ring or both rings of

the bearing. Never place blocks under the outer

into the bearing until the bearing is flush against

ring only. Line up the shaft vertically above the

the shoulder of the shaft). You may use a gear

baring, and place a soft pad between the shaft

puller to remove a rotor bearing, but take

and the press ram. After making sure the shaft

extreme care.

is started straight in the bearing, press the shaft

6. Never remove the bearings unless they are to be

replaced, or unless they must be removed to

allow the removal of the end bells.

7. If you are taking off a ball bearing and plan to

use it again, be careful to apply pressure to the

inner race only. If pressure has been applied to

the outer race, you will have to discard the

bearing.

8. Never use a cleaning solvent on a sealed or a

semi-sealed ball bearing. Store these bearings in

a clean piece of waxed paper until you are ready

to use them.

9. Clean the end bells with a brush and an approved

solvent. Check them for crocks, burrs, nicks,

excessive paint, and dirt.

TESTING COMPONENTS

OF ROTATING ELECTRICAL

MACHINERY

Preventive maintenance of armatures, rotors, or

windings consists mainly of periodic visual inspections

Figure 7-23.--Marking a motor frame and end bell.

and electrical testing to determine the condition of the

7-20