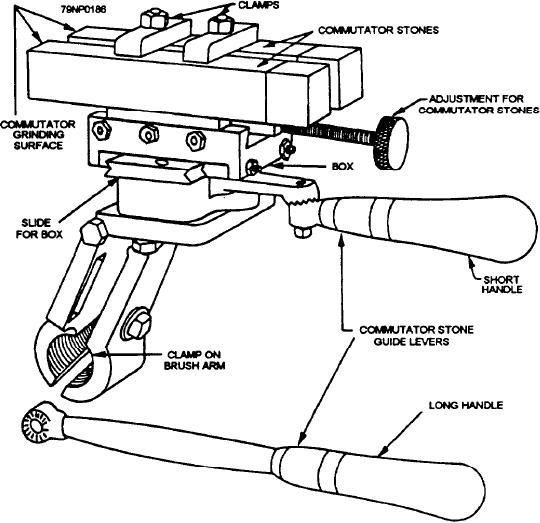

Figure 7-16.--Commutator dressing stone tool.

shock or fouling of moving parts whenever you are

commutator stone against the commutator as the

grinding a motor commutator.

armature is rotated. This method works for some of the

large open and driproof machines. Otherwise, the

A commutator surface stone, when used, should be

armature must be removed from the machine and

rigidly clamped in a holder and supported to keep the

mounted in a lathe and rotated. The commutator stone

stone from chattering or digging into the commutator.

is mounted in the tool post and fed to the commutator,

The support must provide for the axial motion of the

or a rotating precision grinder is mounted in the tool post

stone. To prevent the commutator from having different

and the grinder wheel is fed to the commutator.

diameters at both ends, you should never take heavy cuts

with a stone. Commutator surfacing stones with tool

GRINDING.-- When practical, the armature

post handles are available in the Navy supply system in

should be removed from the machine and placed in a

various sizes and grades (such as free, medium, and

lathe for grinding. If not, the commutator can be ground

coarse).

in the machine, provided there is minimum vibration,

In truing a commutator with a rotating grinder, use

the windings can be adequately protected from grit, and

a medium soft wheel so that the face will not fill up with

suitable supports can accommodate the stone.

copper too rapidly. Even if the commutator is badly

When grinding the commutator in the machine,

distorted, use a light cut, taking as many as needed. If

rotate the armature by using an external prime mover or,

a heavy cut is used, the commutator maybe ground to a

in the case of a motor, by supplying power through just

noncylindrical shape, although initial eccentricity may

enough brushes to take care of the load. You may use

be retained because of the elasticity of the support. The

old brushes for this purpose since the y should be

speed of the wheel should be that recommended by the

manufacturer. The speed of the commutator should be

discarded after grinding. You should avoid electric

7-15