machine rotors should be supported, while being moved

do more damage to a machine during disassembly and

or when stationary, by slings, blocking under the shaft,

assembly than it will receive in years of normal service.

a padded cradle, or thickly folded canvas under the core

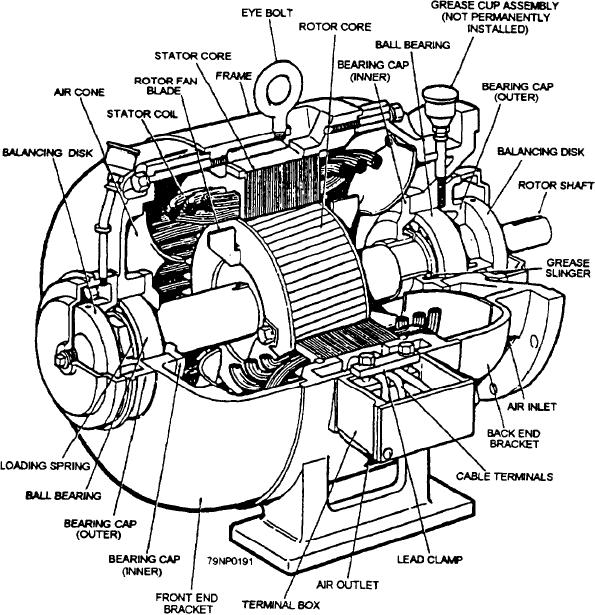

Figures 7-21 and 7-22 show typical ac and dc

laminations. When you are using rope slings to lift ac

motors.

or dc rotors, place them under the shaft, keeping them

clear of the bearing journals. When construction of the

Never be hasty or careless in disassembling a

rotors does not allow room, except around the bearing

generator or motor. Handle the delicate components

journals, you must protect the surfaces with heavy paper

with care to prevent damage or create the need for

or canvas. Ensure rope slings never come in contact

additional adjustment. Use the proper tools, and label

with ac or dc rotor coils. When the complete unit (stator

the parts as you dismantle them. Store them in an

and rotor) is to be lifted by lifting the starer, the bottom

orderly arrangement in a safe place. Note the necessary

of the air gap must be tightly shimmed unless both ends

of the shaft are supported on the bearings. It is possible,

information so that you will have no trouble in

by rough handling or careless use of bars or hooks, to

reassembly.

Figure 7-21.--Typical ac motor.

7-18