CARE OF BRUSHES

All brush shunts should be securely connected to the

brushes and the brush holders. Brushes should move

freely in their holders, but they should not be loose

enough to vibrate in the holder. Before replacing a worn

brush with a new one, clean all dirt and other foreign

material from the brush holder.

Replace old brushes with new brushes when the old

brushes meet the following criteria:

worn or chipped so they will not move properly

in their holders

damaged shunts, shunt connections, or hammer

clips

riveted connections or hammer clips and are

worn to within one-eighth inch of the metallic

part

tamped connections without hammer clips, and

are worn to one-half or less of the original length

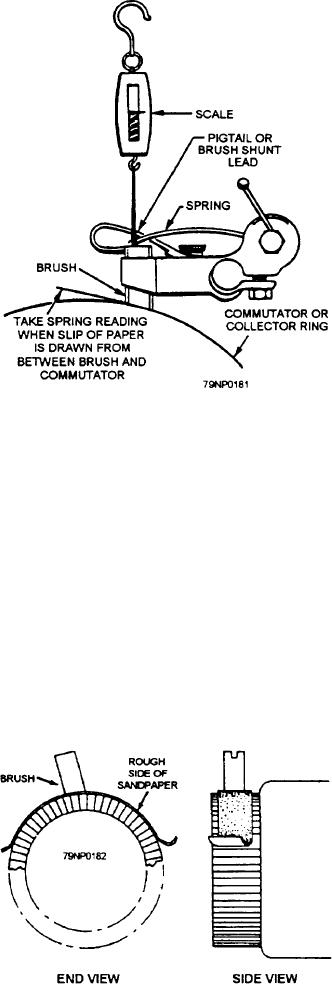

Figure 7-11.--Measuring brush tension.

of the brush; or

divided by the contact area maybe considered to be the

spring-enclosed shunts and are worn to 40

spring operating pressure.

percent or less of the original length of the brush

The toes of all brushes of each brush stud should

(not including the brush head, which fits into one

end of the spring).

line up with each other and with the edge of one

commutator segment.

Where adjustable brush springs are of the positive

gradient (torsion, tension, or compression) type, adjust

The brushes should be evenly spaced around the

them as the brushes wear to keep the brush pressure

commutator. To check brush spacing, wrap a strip of

approximately constant. Springs of the coiled-band,

paper around the commutator and mark the paper where

constant-pressure type, and certain springs of the

the paper laps. Remove the paper from the commutator,

positive gradient type are not adjustable except by

cut at the lap, and fold or mark the paper into as many

changing springs. Adjust pressure following the

equal parts as there are brush studs. Replace the paper

manufacturer's technical manual. Pressures as low as

on the commutator, and adjust the brush holders so that

1 1/2 psi of contact area may be specified for large

the toes of the brushes are at the creases or marks.

machines and as high as 8 psi of contact area may be

specified for small machines. Where technical manuals

are not available, a pressure of 2 to 2 1/2 psi of contact

area is recommended for integral horsepower and

integral kilowatt machines. About twice that pressure

is recommended for fractional horsepower and

fractional kilowatt machines. To measure the pressure

of brushes operating in box-type brush holders, insert

one end of a strip of paper between the brush and

commutator; use a small brush tension gage (such as the

0- to 5-pound indicating scale) to exert a pull on the

brush in the direction of the brush holder axis, as shown

in figure 7-11. Note the reading of the gage when the

pull is just sufficient to release the strip of paper so that

it can be pulled out from between the brush and

Figure 7-12.--Method of sanding brushes.

commutator without offering resistance. This reading

7-10