Oil-Lubricated Ball Bearings

Lubrication charts or special instructions are

generally furnished for electric motors and generators

equipped with oil-lubricated ball bearings. The oil level

inside the bearing housing should be maintained about

even with the lowest point of the bearing inner ring. At

this level, there will be enough oil to lubricate the

bearing for its operating period, but not enough to cause

churning or overheating.

One common method by which the oil level is

maintained in ball bearings is the wick-fed method In

this method, the oil is fed from an oil cup to the inside

of the bearing housing through an absorbent wick. This

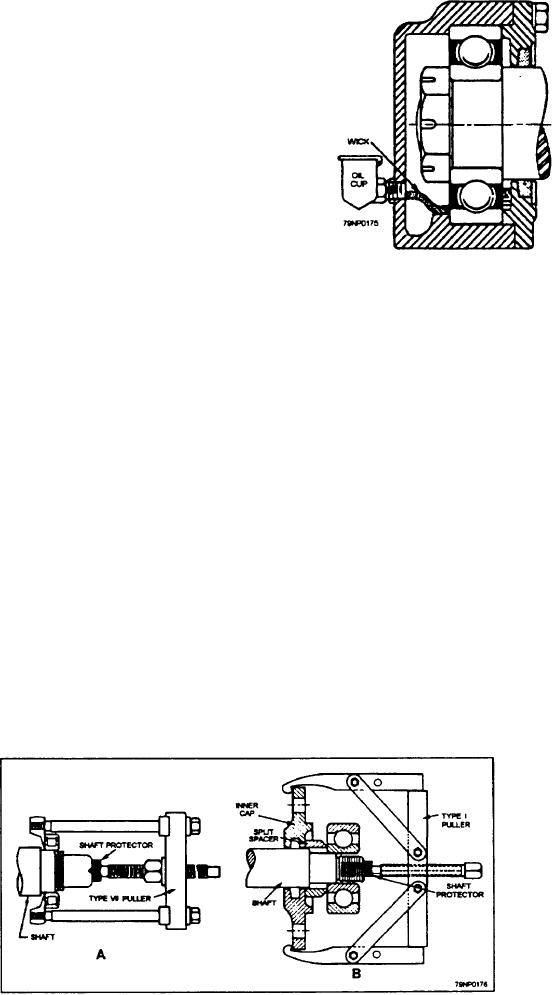

Figure 7-4.--Wkk-fed bell bearings.

wick also filters the oil and prevents leakage through the

are prelubricated. Cleaning will remove the lubricant

cup if momentary pressure is built up within the

from the bearings or can dilute the lubricant until it no

housing. A typical wick-fed, oil-lubricated ball bearing

longer possesses its original lubricating qualities.

is shown in figure 7-4.

Permanently lubricated ball bearings require no

Grease-Lubricated Ball Bearings

greasing. You can recognize equipment furnished with

Preferred Navy bearing greases for shipboard

these bearings by the absence of grease fittings or the

auxiliary machinery are as follows:

provision for attaching grease fittings. When

permanently lubricated bearings become imperative,

1. Bearings operating below 110C (230F) in

replace them with bearings of the same kind. If not

non-noise or noise-critical application should use

already provided, attach DO NOT LUBRICATE

DOD-G-24508 grease. It is available in a 1-pound can

nameplates to the bearing housing of machines with

National

Number (NSN)

Stock

under

sealed bearings.

9150-00-149-1593.

Cleaning Bali Bearings

2. Bearings operating near water (for example,

rudder stock bearings) should use grease MIL-G-24139.

You can clean an open or a single-sealed ball

It is available in a 5-pound can under NSN

bearing only in an emergency when a suitable replace-

9150-00-180-6382.

ment is not available. It is difficult to remove dirt from

ball bearings. Unless the cleaning is carefully done,

NOTE: Other size containers may be available

more dirt may get into the bearings than is removed

under other NSNs.

DOUBLE-SHIELDED OR DOUBLE-SEALED

In cleaning an open, single-shielded or single-

BALL BEARINGS SHOULD NEVER BE

sealed bearing, take the bearing off with a bearing puller

DISASSEMBLED OR CLEANED. These bearings

applied to the inner race of the bearing. Figure 7-5,

Figure 7-5.--Bearing pullers.

7-5