Wear of Bearings

Normally, it is not necessary to measure the air gap

on machines with ball bearings because the construction

of the machines ensures proper bearing alignment.

Additionally, ball bearing wear of sufficient magnitude

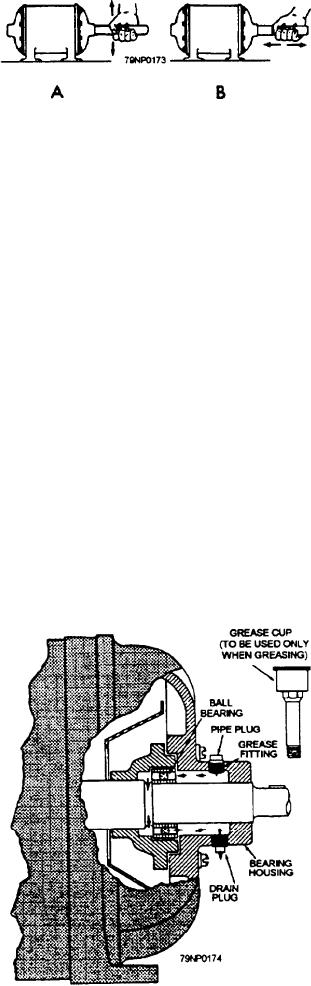

Figure 7-2.--Checking motor or generator shaft. (A) Vertical

as to be readily detected by air-gap measurements would

movements: (B) End-play movement.

be more than enough to cause unsatisfactory operation

of the machine.

Lubrication

The easiest way of determining the extent of wear

A common cause of motor and generator failure is

in these bearings is to periodically feel the bearing

overlubrication. Forcing too much grease into the

housing while the machine is running to detect any signs

bearing housing seals and onto the stationary windings

of overheating or excessive vibration, and to listen to the

and rotating parts of the machine will cause overheating

bearing for the presence of unusual noises.

and deterioration of insulation, eventually resulting in

electrical grounds and shorts. Overheating will also

Rapid heating of a bearing maybe an indication of

cause rapid deterioration of the grease and the eventual

danger. Bearing temperatures that feel uncomfortable

destruction of a bearing. To avoid overlubrication, add

to the touch could be a sign of dangerous overheating,

new lubricant only when necessary.

but not necessarily. The bearing may be operating

properly if it has taken an hour or more to reach that

The frequency that new grease must be added

temperature; whereas, serious trouble can be expected

depends on the service of the machine and the tightness

if high temperatures are reached within the first 10 or

of the housing seals, and the requirements should be

15 minutes of operation.

determined for each machine by the engineering officer

or PMS requirements. A large quantity of grease

The test for excessive vibration relies to a great

coming through the shaft extension end of the housing

extent on the experience of the person conducting the

usually indicates excessive leakage inside the machine.

test. The person should be thoroughly familiar with the

To prevent greasing by unauthorized personnel,

normal vibration of the machines to be able to correctly

grease cups are removed from motors and generators.

detect, identify, and interpret any unusual vibrations.

Pipe plugs are inserted in place of the grease cups. The

Vibration, like heat and sound, is easily telegraphed. A

pipe plugs are replaced temporarily with grease cups

thorough search is generally required to locate the

during lubrication (fig. 7-3). (Removable grease cups

source and determine its cause.

Ball bearings are inherently more noisy in normal

operation than sleeve bearings (discussed later). This

fact must be kept in mind by personnel testing for the

presence of abnormal bearing noise. A common method

for sound testing is to place the blade of a screwdriver

against the bearing housing and the handle against the

ear. If a loud, irregular grinding, clicking, or scraping

noise is heard, trouble is indicated. As before, the

degree of reliance in the results of this test depends on

the experience of the person conducting the test.

Checking the movement of a motor or generator

shaft can also give an indication of the amount of

bearing wear. If the motor shaft has excessive vertical

movement (fig. 7-2, view A), it indicates worn bearings.

Figure 7-2, view B, shows how to get a rough

approximation of motor or generator end-play

movement. You can correct excessive end-play, as

described in the applicable technical manual, by adding

Figure 7-3.--Grease-lubricated ball bearings.

bearing shims.

7-3