If the control circuit continuity check was of a

satisfactory value, the problem is in either the lines to

the motor, the motor, or the main contacts of the

contactor. Check the main contacts of the contactor by

manually operating the contactor and reading the

continuity across the main contacts.

If the main contacts of the contactor read good,

check the lines leading to the motor and the motor

windings themselves. You do this by measuring the

motor winding resistance between the T1 and T2 and T3

points in the controller. If there is a high or infinite

reading at this point, isolate the fault to the motor or lines

leading to the motor by reading the motor winding

resistance in the terminal connection box on the motor.

A good resistance value indicates the fault in the lines

to the motor. A high or inifinite value indicates the fault

is in the motor.

When starting a three-phase motor and the motor

fails to start and makes a loud hum, you should stop the

motor immediately by pushing the stop button. These

symptoms usually mean that one of the phases to the

motor is not energized. You can assume that the control

circuit is good since the main contactor has operated and

the maintaining contacts are holding the main operating

contactor in. Look for trouble in the power circuit

(controller line fuses, main contacts, overload heaters,

cable, and motor).

SUMMARY

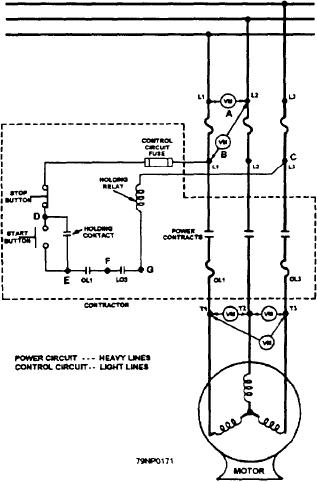

Figure 6-30.--Troubleshooting a thee-phase magnetic line

starter.

In this chapter you were introduced to the

fundamentals of the various ac and dc motor and circuit

control devices to enable you to maintain, troubleshoot,

ohmmeter reads close to zero, the fault is in the contactor

and repair the equipment successfully. Almost all

coil.

equipment installed will have a manufacturer's

By maintaining the one ohmmeter lead on the L1

technical manual that should be used to adjust and repair

control circuit connection point in the controller (point

the equipment following the recommended

A) and moving the other ohmmeter lead along the

specifications. The NSTM, chapter 302, will provide

control circuit (points D then E then F) towards the first

additional information of value to you so that your

ohmmeter lead, you will localize the fault to a faulty

electrical plant will be maintained in the highest state of

readiness.

component or lead.

6-24