button, a reset-emergency run lever, or a

start-emergency run pushbutton. In each of these types,

the lever or push button must be held closed manually

during the entire emergency.

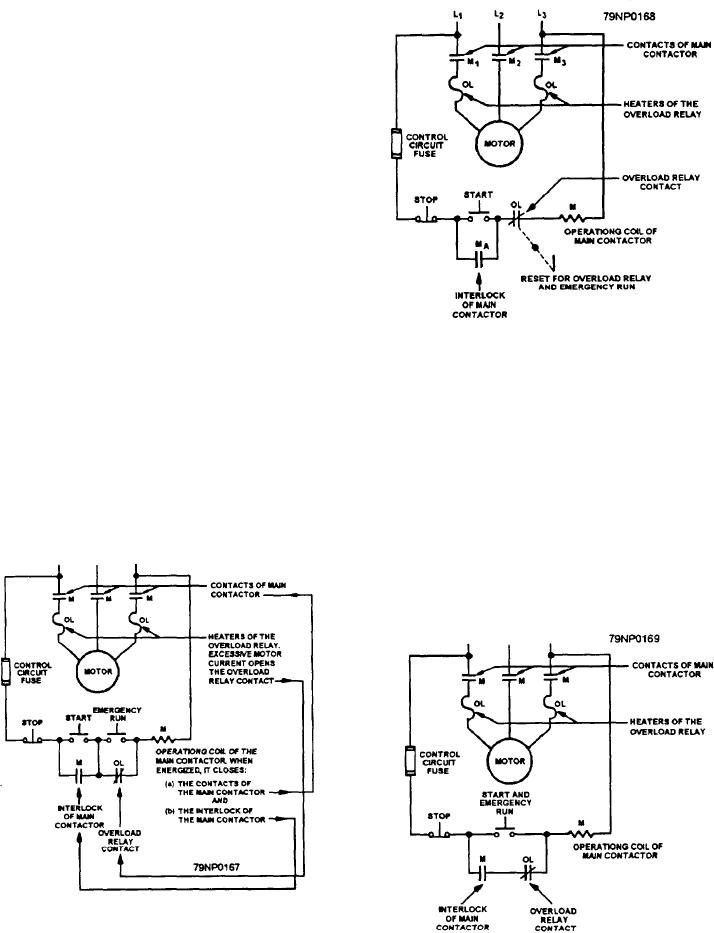

Figure 6-26 is a schematic diagram of a controller

showing a separate EMERGENCY RUN push button

with normally open contacts in parallel with the

normally closed contact of the overload relay. (NOTE:

Like all schematics, this one uses standard symbols to

show the electrical location and operating sequence of

the individual elements or devices, and it does not

indicate their relative physical location.) For

emergency run operation, the operator must hold down

this push button and press the START button to start the

motor. While the emergency run push button is

depressed, the motor cannot be stopped by opening the

overload relay contact.

A RESET-EMERGENCY RUN lever is shown in

Figure 6-27.--Schematic of controller with reset-emergency

figure 6-27. As long as the lever or rod is held down,

lever or rod.

the overload relay contact is closed. The start button

must be momentarily closed to start the motor. Figure

6-28 shows a START-EMERGENCY RUN push button.

marked start-emergency run should not be kept closed

The motor starts when the button is pushed and

for more than a second or two unless the emergency run

continues to run without overload protection as long as

operation is desired.

it is held down. For this reason, push buttons that are

Manual controllers may also be provided with an

emergency run feature. The usual means is a

start-emergency run push button or lever, which keeps

the main contactor coil energized despite the tripping

action of the overload relay mechanism.

Figure 6-28.--Schematic of controller with start-emergency

Figure 6-26.--Schematic of controller with emergency run

run push button.

push button.

6-19