controller circuit must be checked for possible fault. As

the overload relay reset push button. Then attempt to

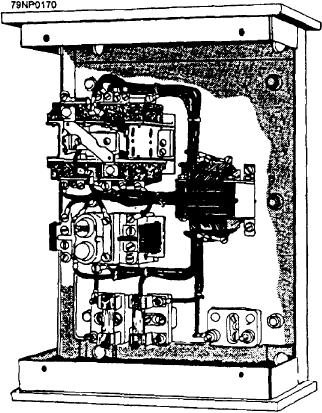

you read this section, refer to figures 6-29 and 6-30.

start the motor. If the motor operation is restored, no

further checks are required. However, if you hear the

Remove the controller line fuses or verify that the

controller contacts close but the motor fails to start, then

fuses are removed. Danger tag the controller line fuses

check the motor circuit continuity. If the main contacts

that have been removed and taking the applicable

don't close, then check the control circuit for continuity.

electrical safety precautions according to NSTM,

An example of troubleshooting a motor-controller

chapter 300, check the controller de-energized.

electrical system is given in a sequence of steps that may

be used in locating a fault:

Using an ohmmeter, check the continuity of the

control circuit between the L1 and the L3 connection

1. Symptom recognition-recognize the normal

points (point A and B of fig. 6-30) in the controller while

operation of the equipment

holding the start button in the START position. If the

2. Symptom elaboration-recognize/observe the

control circuit is good, the ohmmeter should read a

faulty operation of the equipment

resistance equivalent to the resistance value of the

3. Listing of probable faulty functions-develop a

contactor coil. Depending on the size of the coil, this

list of possible causes for the malfunction

value could be anywhere from a couple hundred ohms

to a couple thousand ohms. If the ohmmeter reading is

4. Localizing the fault-determine the most likely

infinite, the problem is in the control circuit.

areas of failure to create the symptoms noted

5. Localizing the trouble to the circuit-using test

To isolate the fault in the control circuit, leave one

equipment, isolate the malfunction down to the

of the ohmmeter leads on the L1 control circuit

most likely component(s)

connection point (point A) and move the other lead of

the ohmmeter to the other side of the contactor coil in

6. Failure analysis-verify the component(s) is/are

the controller (point C). If while holding the start button

faulty

in the ON position the ohmmeter reads infinite, the fault

Let's start by analyzing the power circuit.

is between point A and C in the control circuit. If the

POWER CIRCUIT ANALYSIS

When no visual signs of failure can be located and

an electrical failure is indicated in the power circuit, you

must first check to see if power is available and the line

fuses are good. See if the supply source is available by

checking that the feeder breaker is shut and other

equipment receiving power from that breaker is

operational. Only under extremely rare situation would

there be a break in the cabling going to the line fuses.

Taking applicable electrical safety precautions

according to NSTM, Chapter 300, remove the line fuses

and check the continuity of the fuses. While removing

the fuses, check for lose fuse clips which could give a

faulty connection to the line fuse. If power is available

and the line fuses are good, then the problem is in either

the control circuit, the motor line leads, or the motor

itself.

CONTROL CIRCUIT ANALYSIS

Taking applicable electrical safety precautions

according to NSTM, chapter 300, remove the control

fuse and check the fuse continuity. If the fuse is bad,

replace the fuse with a fuse of proper size and rating and

Figure 6-29.--Typical three-phase controller.

retest the controller. If the control fuse is good, the

6-23