CAUTION

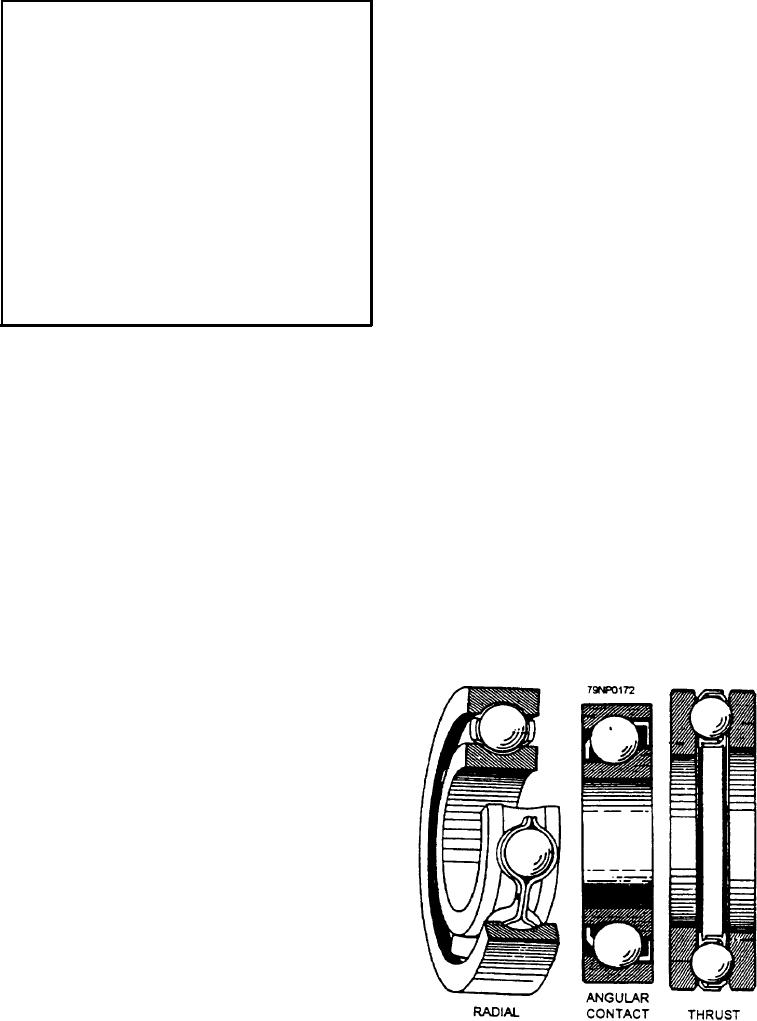

the Navy. These bearings are further divided into the

following three types (fig. 7-1), depending on the load

Be careful when using compressed air,

they are designed to bear:

particularly if abrasive particles are present

1. Radial. Radial bearings are capable of

because they may be driven into the insulation

supporting combined high radial and thrust

and puncture it or be forced beneath the

loads, but they aren't self-aligning. Therefore,

insulating tape. Compressed air should be used

accurate alignment between the shaft and

only after the equipment has been opened on

housing is required.

both ends to allow the air and dust to escape.

The use of compressed air will be of little

2. Angular contact. Angular contact bearings are

benefit if the dust is not suitably removed from

designed to take radial and thrust loads where

the equipment. The most suitable method to

the thrust component may be large.

remove dirt-laden air is to place a suction hose

3. Thrust. Thrust bearings are used when the load

on the opposite end of the equipment where

is completely axial rather than radial.

compressed air is being used

The ball bearings on a rotating shaft of an electric

Whenever possible, avoid the use of solvents for

motor or generator may be subjected to radial thrust

cleaning electrical equipment. However, their use is

and/or angular forces. While every ball bearing is not

necessary for removing grease and pasty substances

subjected to all three forces, any combination of one or

consisting of oil and carbon or dirt. Alcohol will injure

more may be found depending on the equipment design.

most types of insulating varnishes, and it should not be

Radial loads are the result of forces applied to the

used for cleaning electrical equipment. Because of their

bearing perpendicular to the shaft; thrust loads are the

high toxicity, solvents containing gasoline, benzene, and

result of forces applied to the bearing parallel to the

carbon tetrachloride must NEVER be used for cleaning

shaft; and angular loads are the result of a combination

purposes. Refer to chapter 1 of this manual and NSTM,

of radial and thrust loads. The load carried by the

chapter 300, for detailed information on the use of

bearings in electric motors and generators is almost

solvents for cleaning electrical machinery.

entirely due to the weight of the rotating element. For

Motors, generators, and other electrical equipment

this reason, the method of mounting the unit is a major

that have been wet with salt water should be flushed out

factor in the selection of the type of bearing installed

with fresh water and dried. Never let the equipment dry

when they are constructed. In a vertically mounted unit,

before flushing it with fresh water. For complete

the thrust bearing is used, while the radial bearing is

information on washing and drying procedures, refer to

normally used in most horizontal units.

NSTM, chapter 300.

BEARINGS

Bearings are designed to allow a rotating armature

or rotor to turn freely within a motor or generator

housing. Shaft bearings must be properly maintained to

reduce the heat caused by friction.

The two common types of bearings found in motors

and generators are antifriction bearings and friction

bearings.

ANTIFRICTION BEARINGS

There are two types of antifriction bearings--ball

and roller. Basically, both types consist of two hardened

steel rings, hardened steel rollers or balls, and

separators. The annular, ring-shaped ball bearing is the

type of roller bearing used most extensively in the

construction of electric motors and generators used in

Figure 7-1.--Representative types of ball bearings.

7-2