method should not be used unless absolutely necessary.

cut only 3/4 of the way through the seized inner

The disadvantages of the hot-oil method are the lack of

ring in order to prevent damage to the shaft.

temperature control, the possibility of bearing

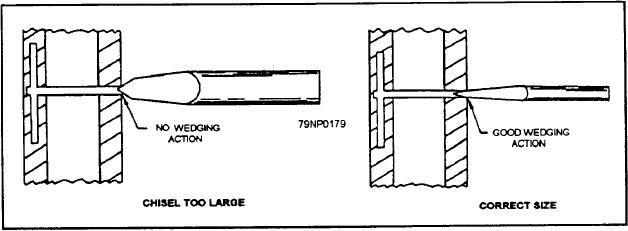

7. Using the correct size chisel, as shown in figure

enlargement and grease deterioration or contamination

7-8, crack the bearing inner ring and remove it.

by dirty oil.

For additional methods of bearing installation, refer

Bearing Installation

to NSTM, chapter 244.

There are two acceptable methods for installing

FRICTION BEARINGS

bearings-the arbor press method and the heat method.

ARBOR-PRESS METHOD.-- When available

Friction bearings are of three types:

and adaptable, you can use an arbor press if you take the

proper precautions. Place a pair of flat steel blocks

is parallel to the elements of a sliding surface.

under the inner ring or both rings of the bearing. Never

place blocks under the outer ring only. Then, lineup the

2. Journal. In journal friction bearings, two

shaft vertically above the bearing, and place a soft pad

machine parts rotate relative to each other.

between the shaft and press ram. After making sure the

3. Thrust. In thrust bearings, any force acting in

shaft is started straight in the bearing, press the shaft into

the direction of the shaft axis is taken up.

the bearing until the bearing is flush against the shaft or

housing shoulder. When pressing a bearing onto a shaft,

Turbine-driven, ship's service generators and

always apply pressure to the inner ring; when pressing

propulsion generators and motors are equipped with

a bearing into a housing, always apply pressure to the

journal bearings, commonly called sleeve bearings. The

outer ring.

bearings may be made of bronze, babbitt, or

steel-backed babbitt. Preventive maintenance of sleeve

HEAT METHOD.-- A bearing can be heated in an

bearings requires periodic inspections of bearing wear

oven or furnace to expand the inner ring for assembly.

and lubrication.

This method ensures uniform heating all around the

bearing.

Wear of Bearings

Heat the bearing in an infrared oven or a

temperature-controlled furnace at a temperature not to

Propulsion generators, motors, and large ship's

exceed 203 10F (89.4 to 100.6C). The bearing

service generators are sometimes provided with a gage

should be left in the oven or furnace only for enough

for measuring bearing wear. You can obtain bearing

time to expand the inner race to the desired amount.

wear on a sleeve-bearing machine not provided with a

Prolonged heating could possibly deteriorate the

bearing by measuring the air gap at each end of the

prelubrication grease of the bearing. The bearing may

machine with a machinist's tapered feeler gage. Use a

also be heated in oil at 203 10F (89.4 to 100.6C)

blade long enough to reach into the air gap without

removing the end brackets of the machine. Before

until expanded, and then slipped on the shaft. This

Figure 7-8.--Cracking seized inner ring of bearing.

7-7