RENEWAL OF GREASE WITHOUT

should remain in the custody of the responsible

maintenance personnel.) Make sure the grease cups are

DISASSEMBLING THE BEARING HOUSING.--

clean. After the grease is added, clean the pipe plugs

Do not try to add new grease without at least partially

before replacing them.

disassembling the bearing housing unless the following

conditions exist:

The preferred method of adding grease calls for

The machine is horizontal. There is no adequate

disassembly of the bearing housing. Although not

recommended, renewing the bearing grease without at

means of protecting the windings against

least partially disassembling the housing may be tried

displaced lubricant in vertical machines.

under certain conditions (given later).

A suitable fitting is provided for admitting

RENEWAL OF GREASE BY DIS-

grease. If a grease-gun fitting is provided, it

ASSEMBLING THE BEARING HOUSING.-- The

should be replaced by a grease cup when you add

extent of disassembly necessary will depend on the

grease.

construction of the bearing, Bearings with outer bearing

The drain hole on the bearing housing is

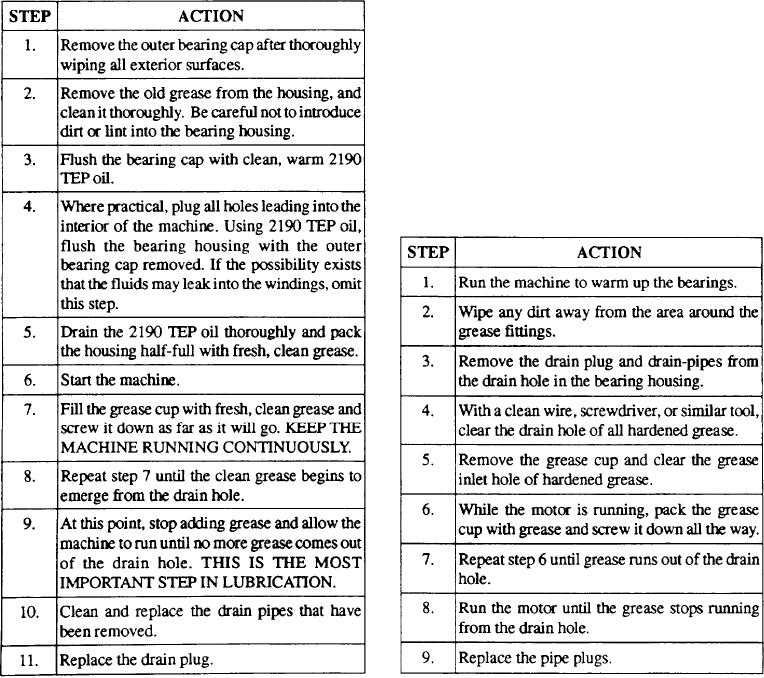

caps should be disassembled as described in table 7-1:

accessible. Drainpipes do not permit satisfactory

Table 7-1.--Renewal of Grease by Disassembly of the Bearing

escape of displaced grease, and should be

Housing

removed when renewing grease.

The machine is running continuously while

removing grease. If the machine cannot be run

continuously during the greasing period without

injuring the driven auxiliary or endangering

personnel, the bearing housing must be

disassembled to renew the grease.

If one or more of the above conditions exist, renew

the grease in assembled bearing housings by the method

in table 7-2:

Table 7-2.--Renewal of Grease in Assembled Bearing Housings

7-4