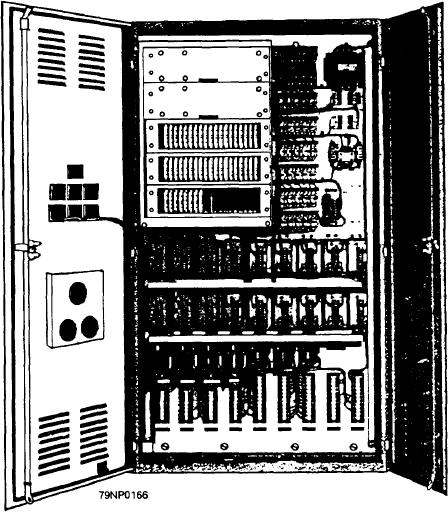

Figure 6-25.--A static logic panel for a cargo elevator.

unaffected by variations in the ambient (room)

operating coil of the main contactor and disconnects the

temperature. Different compensation methods are used

motor from the power supply. Since it takes time for the

for different types of thermal overload relays. Refer to

parts to heat up, the thermal overload relay has an

inherent time delay, which allows the motor to draw

the technical manual furnished with the equipment on

excessive current at start without tripping the motor.

which the controller is used for information on the

particular form of compensation provided. There are

You can make a coarse adjustment of the tripping

four types of thermal overload relays--solder pot,

current of thermal overload relays as follows:

bimetal, single metal, and induction.

Change the heater element.

SOLDER POT THERMAL OVERLOAD

RELAY.-- The heat-sensitive element of a solder-pot

Change the distance between the heater and the

relay consists of a cylinder inside a hollow tube. The

heat-sensitive element to make a fine adjustment.

cylinder and tube are normally held together by a film

An increase in this distance increases the tripping

of solder. In case of an overload, the heater melts the

current. (NOTE: Making fine adjustments

solder (thereby breaking the bond between the cylinder

depends on the type of overload relay.)

and tube) and releases the tripping device of the relay.

Change the distance the bimetal strip has to move

After the relay trips, the solder cools and solidifies. The

before the overload relay contact is opened.

relay can then be reset.

Check the related technical manual for additional

BIMETAL THERMAL OVERLOAD

information and adjustments.

RELAY.-- In the bimetal relay, the heat-sensitive

element is a strip or coil of two different metals fused

Thermal overload relays must be compensated; that

together along one side. When heated, the strip or coil

is, they are constructed so the tripping current is

6-17