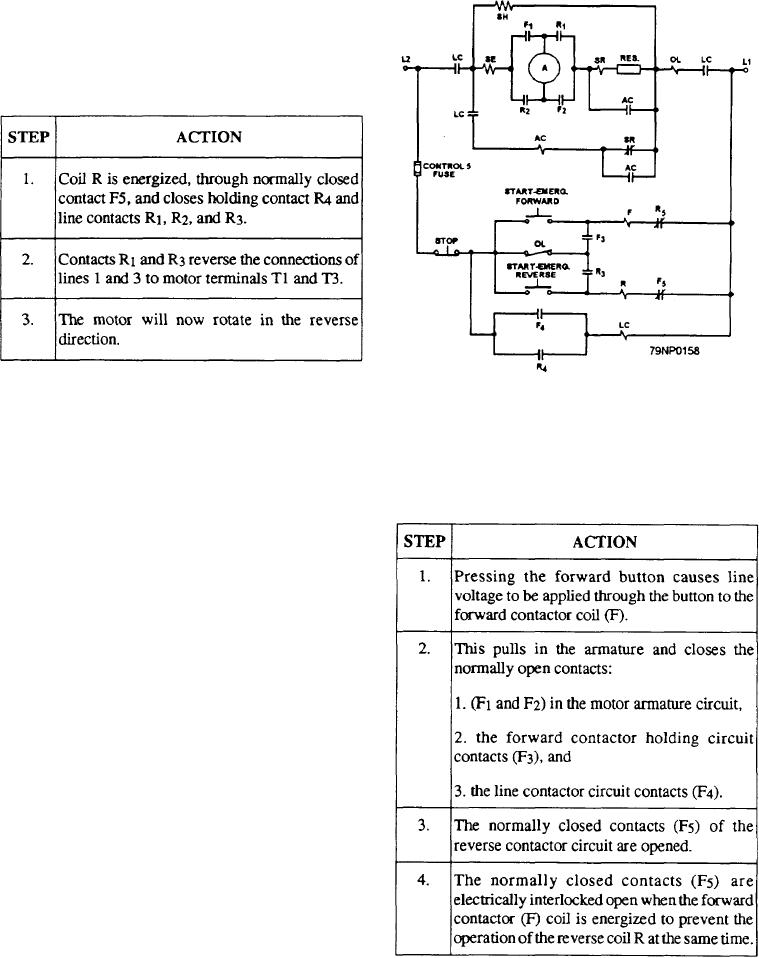

The operation of the reversing motor in the reverse

position is shown in table 6-8. After the reverse push

button is pressed (solid to dotted position):

Table 6-8--Reverse Operation of a Reversing AC Controller

The F and R contractors are both mechanically and

Figure 6-17.--Reversing dc controller.

electrically interlocked to prevent both being closed at

the same time.

The forward operation of the reversing dc controller

Momentary contact push buttons provide

is given in table 6-9.

low-voltage protection with manual restart in the

Table 6-9.--Forward Operation of a DC Controller

circuit shown in figure 6-16. If either the F or R

operating coil is de-energized, the contactor will not

reclose and start the motor when voltage is restored

unless either the forward or reverse push button is

pressed. The circuit arrangement of the normally

closed contacts F5 and R5 provides an electrical

interlock that prevents the energizing of both coils at the

same time.

DC Motors

In most applications, the direction in which a dc

motor turns is reversed by reversing the connections of

the armature with respect to the field. The reversal of

connections can be done in the motor controller by

adding two electrically and mechanically interlocked

contractors.

A dc motor reversing connection is shown in figure

6-17. Note that there are two start buttons--one marked

START-EMERG FORWARD and the other marked

START-EMERG REVERSE. These buttons serve as

master switches, and you can get the desired motor

After the line contactor is energized, acceleration is

rotation by pressing the proper switch.

accomplished in the reamer described previously.

6-12