Low-Voltage Release (LVR)

The LVR controller (fig. 6-13) operates in basically

the same way as the LVP controller, except that its start

switch is a maintaining-type switch, such as a snap

switch. This makes the use of a maintaining circuit,

through an auxiliary contact in parallel with the start

switch, unnecessary.

If power is lost to a motor supplied by an LVR

contactor while it is operating, the motor will stop just

as if it had been turned off. Once power is restored, the

motor will restart since the start circuit was maintained

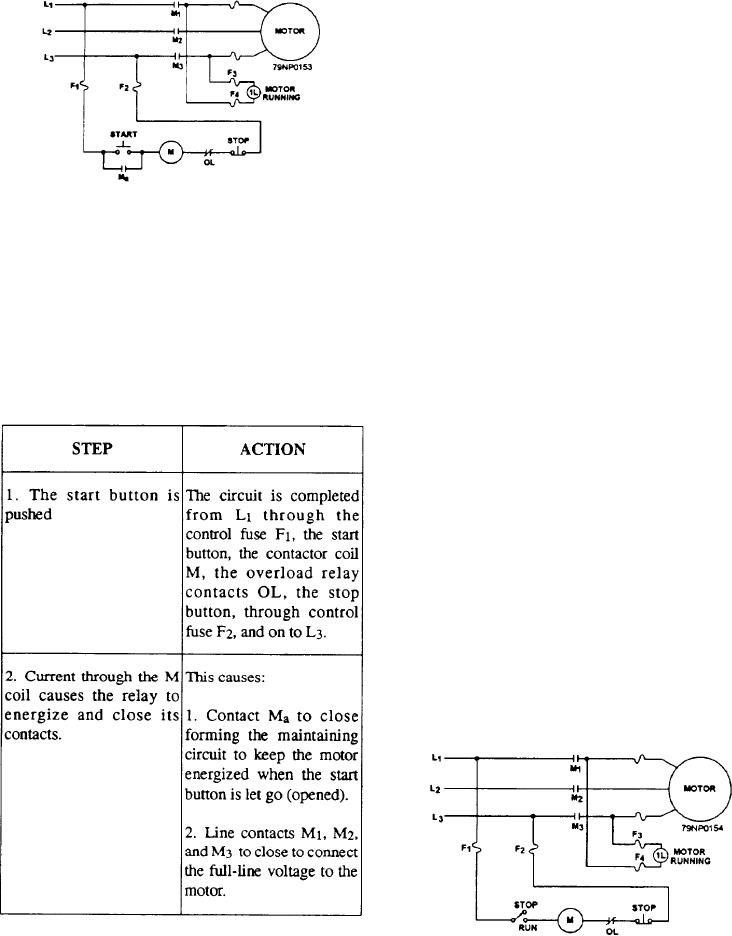

Figure 6-12.--Schematic of a simple LVP controller.

through the maintaining-type start switch. For this

reason, motors that drive loads requiring some setup by

the operator before being energized are normally

Low-Voltage Protection (LVP)

controlled by LVP controllers.

An elementary or schematic diagram of an LVP

Low-Voltage Release Effect

magnetic controller is shown in figure 6-12. Table 6-2

(LVRE)

describes the sequence of operation in starting the

motor:

The LVRE controller is actually a simple switch. It

operates in the same way as the LVR controller, except

Table 6-2.--Operation of a Simple LVP Controller

that it doesn't have a coil in its circuit to operate contacts.

The main contacts are operated by the operator

manually opening and closing the start switch. A

household light switch is an example of an LVRE

controller.

SPEED SELECTION CONTROLLERS

Both ac and dc motors maybe designed to operate

at more than one speed. In each case, controllers are

used to select the desired operating speed and protect

the motor.

The most common type of motor in the fleet is the

ac, squirrel-cage induction motor. The speed of this

The motor will continue to run until the contactor

coil is de-energized by the stop push button, failure of

Figure 6-13.--Schematic of simple LVR controller.

the line voltage, or tripping of the overload relay, OL.

6-8