You can check the operation and contact spacing by

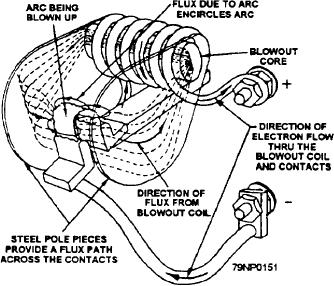

chosen to match the current so that the correct amount

of flux may be obtained. The blowout flux across the

manually closing the contactor (be sure the power is

arc gap is concentrated by the magnetic path provided

off). The lowest leaf of brush contact 6 should just

by the steel core in the blowout coil and by the steel pole

barely touch contact 5. If the lower leaf hits the plate

pieces extending from the core to either side of the gap.

too soon, bend the entire brush assembly upward

slightly. The contact dimensions should be measured

with the contactor in the OPEN position.

AC Contractors

Refer to the manufacturer's instruction book when

making these adjustments.

AC contractors (fig. 6-11) and control relays differ

BLOWOUT COILS.-- When a circuit carrying a

from DC contractors and control relays in three general

high current is interrupted, the collapse of the flux

areas:

linking the circuit will induce a voltage, which will

1. For heavy currents, ac contractors generally use

cause an arc. If the spacing between the open contacts

an air gap alone to quench the arc created by

is small, the arc will continue once it is started. If the

opening energized contacts while dc contractors

arc continues long enough, it will either melt the

use blowout coils.

contacts or weld them together. Magnetic blowout coils

overcome this condition by providing a magnetic field

2. AC contractors are noisier than dc contractors.

that pushes the arc away from the contact area.

Shading bands are sometimes used on ac

contactor cores to reduce noise and produce

The magnetic blowout operation is shown in figure

smoother operation.

6-10. It is important that the fluxes remain in the proper

relationship. Otherwise, if the direction of the current

3. The coil of an ac contactor contains fewer turns

is changed, the direction of the blowout flux will be

of wire than a dc contactor for the same voltage;

reversed, and the arc will actually be pulled into the

therefore, it depends on inductive reactance to

space between the contacts.

produce counterelectromotive force (cemf) to

limit current flow in the coil. If an ac contactor

When the direction of electron flow and flux is as

fails to close completely, an air gap will exist in

shown in figure 6-10, the blowout force is upward. The

the magnetic circuit. This air gap reduces the

blowout effect varies with the magnitude of the current

amount of cemf produced which reduces the

and with the blowout flux. The blowout coil should be

ability of the coil to protect itself and may lead

to burnout of the coil.

The operating parts of the contactor must be kept

clean and free to operate to prevent burnout of the coils.

A regular maintenance routine of cleaning and circuit

testing according to prescribed PMS will keep

contractors free of trouble for years of operation.

CONTROLLER OPERATION

The operation of the various types of controllers is

discussed in this section of the TRAMAN.

MAGNETIC ACROSS-THE-LINE

CONTROLLERS

Across-the-line controllers are the most common

motor controllers you will encounter aboard ship. Of

Figure 6-10.--Action of a magnetic blowout coil.

the three types (LVP, LVR, and LVRE), LVPs are most

often used aboard ship to control/protect motors.

6-6