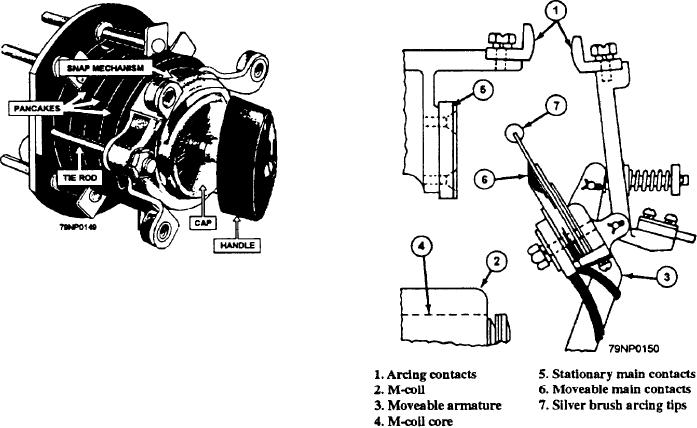

Figure 6-8.--Rotary snap switch.

Master switches may start a series of operations

when their contacts are either closed or opened. In a

momentary contact master switch, the contact is closed

(or opened) momentarily; it then returns to its original

condition. In the maintaining contact master switch, the

contact does not return to its original condition after

closing (or opening) until it is again actuated. The

Figure 6-9.--Detailed view of arcing contacts.

position of a normally open or normally closed contact

in a master switch is open or closed, respectively, when

The blowout shield has been removed in this detailed

the switch is de-energized. The de-energized condition

view. As you read this section refer to figure 6-9.

of a manual controller is considered to be in the OFF

position

The arcing contacts (1) are made of rolled copper

with a heavy protective coating of cadmium. These

contacts are self-cleaning because of the sliding or

CONTRACTORS

wiping action following the initial contact. The wiping

action keeps the surface bright and clean, and thus

Contractors are the heart of any controller. They

maintains a low contact resistance.

operate to open and close the contacts that energize and

de-energize connected loads.

The contactor is operated by connecting the coil (2)

directly across a source of dc voltage. When the coil is

DC Contractors

energized, the movable armature (3) is pulled toward the

stationary magnet core (4). This action causes the

A dc contactor is composed of an operating magnet

contacts that carry current (5, 6, 7, and 1) to close with

a sliding action

energized by either switches or relays, fixed contacts,

and moving contacts. It maybe used to handle the load

The main contacts (5 and 6), called brush contacts,

of an entire bus or a single circuit or device. Larger

are made of thin leaves of copper that are backed by

contacts must be used when heavy currents are to be

several layers of phosphor bronze spring metal. A silver

interrupted. These contacts must snap open or closed to

brush arcing tip (7) is attached to the copper leaves and

reduce contact arcing and burning. In addition to these,

makes contact slightly before the leaf contact closes.

other arc-quenching means are used.

The stationary contact (5) consists of a brass plate,

ARCING CONTACTS.-- The shunt contactor

which has a silver-plated surface. Since the plating

shown in figure 6-9 uses a second set of contacts (1) to

lowers the surface resistance, the contact surfaces

reduce the amount of arcing across the main contacts (5

should never be filed or oiled. If excessive current

and 6) when closing. The numbers that are in

causes high spots on the contact, the high places maybe

parentheses are indicated on the figure. Shunt-type

smoothed down by careful use of a fine ignition-type

contractors will handle up to 600 amperes at 230 volts.

file.

6-5