However, a motor generator or static converter will still

Load-measuring circuits are used in the

be required for type III voltage control.

electrohydraulic governor to obtain proper load sharing

on each paralleled generator. Most governing systems

NOTE: Refer to chapter 8 of this TRAMAN to

are designed so that any change in load produces a

identify the characteristics of type II and type III power.

signal that is fed into the electronic amplifier. This acts

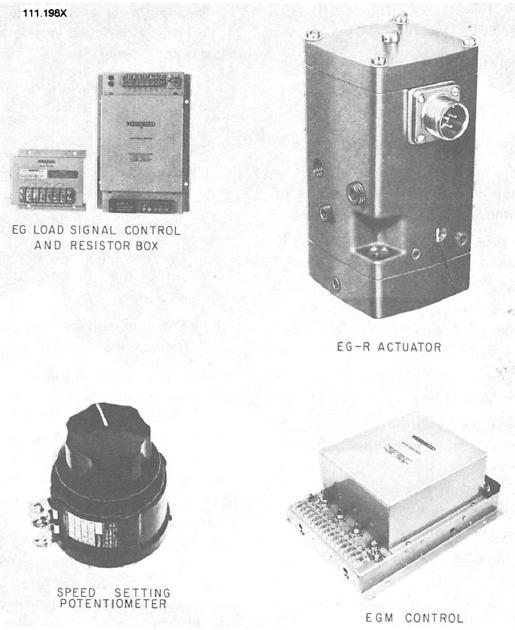

The electrohydraulic load-sensing governor used in

to offset any anticipated speed change caused by load

this chapter is made up of three separate assemblies (fig.

change. The load-measuring circuits of governors on all

9-1)--an EG-M control box, a speed-adjusting

generators that operate in parallel are connected by a

potentiometer, and a hydraulic actuator. Depending on

bus tie cable. The governor maybe designed or preset so

the control box and the type of service in which it is

that each paralleled generator will equally share the

used, a load signal box and a resistor box may be

total load. If not, a load-sharing adjustment must be

required

provided.

EGM SYSTEM

The steady state and transient frequency

The EG-M electrohydraulic governor system (fig. 9-

requirements for type II electrohydraulic governors

2) offers diversified work capabilities. Large or small

power can be met with of the type just described.

prime mover governor requirements can be met by the

Figure 9-1.--Electrohydraulic load-sensing governor system components.

9-2