mount the overload relay on the mounting plate.

Replace the heater coils as the last operat.ion.

Overload relays are PROTECTIVE DEVICES.

After an overload relay has performed its safeguarding

function, you must reset it before running the system

again with overload protection.

REVERSE-POWER RELAY

On all ships with ac ship's service power systems

where the generators are operated in parallel, each

generator control unit has a reverse-power relay. The

approximate] y 10 seconds with reverse power equal to

5 percent of the generator rating.

Reverse-power relays trip the generator circuit

breaker to prevent motoring the generator. This

protection is provided primarily for the prime mover or

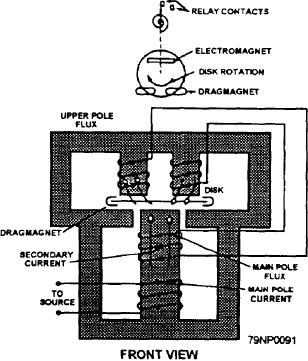

Figure 2-44.--A coil and disk arrangement of an ac

system, rather than for the generator. Motoring results

reverse-power relay.

from a deficiency in the prime mover input to the ac

generator. This deficiency can be caused by loss of or

low steam to the turbine, lack of fuel to the diesel engine

The main relay contacts (not shown in fig. 244) will

or gas turbine, or other factors that affect the operation

safely handle 30 amperes at 250 volts dc and will carry

of the prime mover. In the absence of reverse-power

the current long enough to trip a breaker.

protection, when the input to the generator falls below

The induction disk is rotated by an electromagnet in

that needed to maintain synchronous generator speed,

real power is taken from the ship's service power

the rear of the assembly. Movement of the disk is

damped by a permanent magnet in front of the assembly.

system. The generator acts as a motor driving the prime

mover. Reverse-power protection prevents damage to

The operating torque of the timer element is

the prime mover if a reverse-power condition should

obtained from the electromagnets (fig. 2-44). The

occur.

main-pole coil is energized by the line voltage. This coil

then acts as the primary of a transformer and induces a

The reverse-power relay consists of two induction

voltage in the secondary coil. Current then flows

disk-type elements. The upper element is the timer, and

through the upper pole coils. This produces a torque on

the lower one is the direction element. Figure 2-44

the disk because of the reaction between the fluxes of

shows the coil and induction disk arrangement in the

the upper and lower poles.

induction-type relay timer element. The disk is 4 inches

in diameter and is mounted on a vertical shaft. The shaft

The timer element cannot be energized unless the

power flow is in the direction that will cause tripping.

This interlocking action is accomplished by connection

An arm is clamped to an insulated shaft, which is

of the timer potential coil in series with the contacts of

geared to the disk shaft. The moving contact, a small

the directional element. Thus, the direction of power

silver hemisphere, is fastened on the end of the arm. The

flow controls the timer relay.

electrical connection to the contact is made through the

arm and a spiral spring. One end of the spring is

The directional element is similar to the timing

fastened to the arm and the other end to a slotted

element, except that different quantities are used to

spring-adjusted disk fastened to a molded block

produce rotation of the disk. There is also a different

mounted on the element frame. The stationary contact

contact assembly. The two upper poles of the

is attached to the free end of a leaf spring. The spring

electromagnet are energized by a current that is

is fastened to the molded block, and a setscrew makes

proportional to the line current, and the lower pole is

it possible to adjust the stationary contact position.

energized by a polarizing voltage. The fluxes produced

2-38