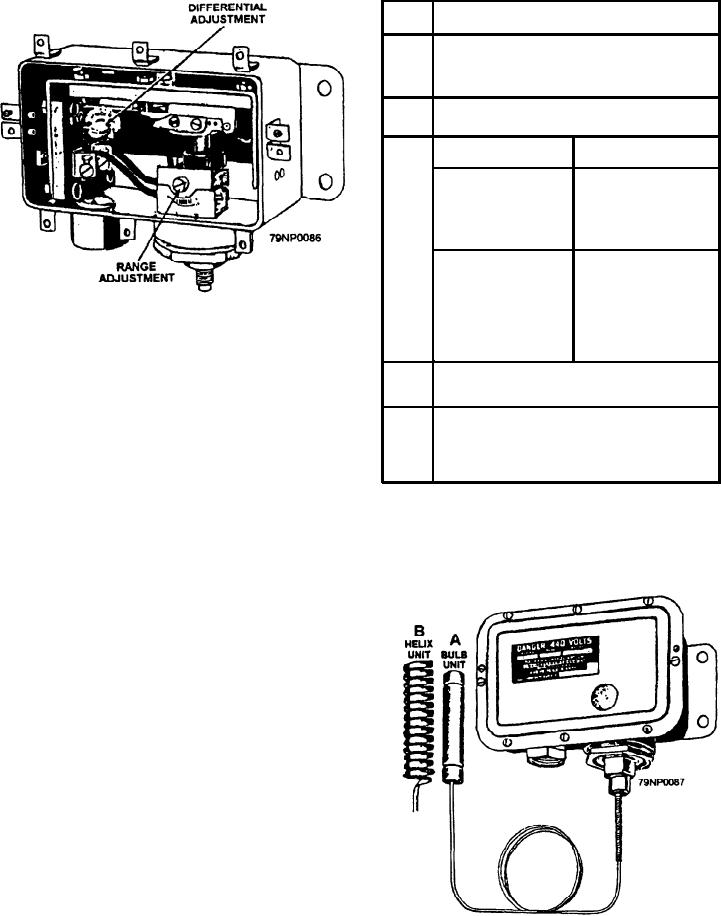

Table 2-8.--Steps to adjust pressure operated switches

ACTION

STEP

Turn the differential adjustment screw (fig.

1

2-39) counterclockwise against the stop for

minimum differential.

2

Bring the system pressure to that at which

you wish the switch to close.

THEN

IF

3

Turn the range screw

Contacts are open

slowly clockwise

when the desired

until the contacts just

temperature is

close.

reached.

Turn the range screw

Contacts are closed

slowly

when the desired

counterclockwise

temperature is

until the contacts

reached.

Figure 2-39.--A pressure-operated switch.

open; then clockwise

until they just close.

the same regardless of the kind of pilot device

4

Bring the system to the pressure at which

you wish the switch to open.

used to control the circuit. To maintain more or

less constant temperature or pressure, switch

Turn the differential adjustment screw

5

slowly clockwise to widen the differential

contacts are arranged to close when the pressure

until the desired opening pressure is

or temperature drops to a predetermined value

obtained.

and to open when the pressure or temperature

rises to the desired value. The reverse action

Thermal Unit Type

can be obtained by a change in the contact

positions.

The bulb and helix units can be connected to the

The difference in pressure for contact opening and

switch section (fig. 2-40). The bulb unit (fig. 2-40, view

closing is the differential. The switch mechanism has a

built-in differential adjustment so that the differential

can be varied over a small range. Once set, the

differential remains essential y constant at all pressure

settings.

Each switch has a range adjustment that sets

the point at which the circuit is closed. Changing

the range adjustment raises or lowers both the

closing and opening points without changing the

differential.

Adjustments

The following table describes the steps in adjusting

pressure operated switches (table 2-8);

Figure 2-40.--Thermal units.

2-33