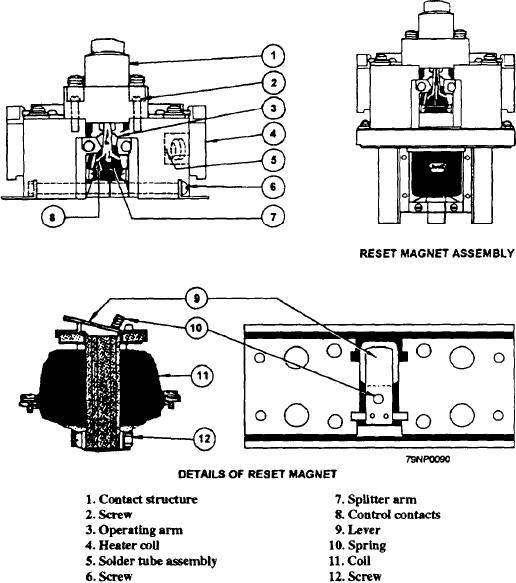

Figure 2-43.--An adjustable thermal overload relay and a reset magnet assembly.

The adjustable thermal relay may be adjusted to trip

have reset magnet assemblies attached. You may have

at a value between 90 to 110 percent of the rated coil

to replace the heater coils from the relay. If so, remove

current. To change the operating point, loosen the

the four screws that hold the overload relay to the

binding screws that hold the relay heater coil (4) so that

mounting plate. When removing the relay from the

the coil position may be changed. Moving the coil away

mounting plate, use care not to lose the phenolic pin and

from the relay will increase the amount of current

bearing block located between the thermal blocks on the

needed to trip the relay. Moving the coil closer to the

underside of the relay.

relay will decrease the current needed to trip the relay.

This range of adjustment is available only within the

Next, remove the four large countersunk screws that

range of 90 to 110 percent of coil rating. Each rating

hold the mounting plate and the reset magnet assembly

has a different manufacture part number. The correct

to the square posts. Remove the four screws in the

rating is installed when the controller is installed in the

mounting plate, which support the reset magnet. Take

ship. Do not use another rating. Make sure both heater

care not to loosen the lever and spring (9 and 10).

coils in each overload relay are the same rating.

Remove the two screws (12) and pull the plunger guides.

Remove the old coil (11) and install the new coil. Then

The terminal plates and the underside of the slotted

insert the plunger guides and replace the screws (12).

brackets of the heater coil assembly are serrated so that

Reassemble the magnet, spring, and lever to the

the coil is securely held in position when the binding

screws are tightened. Some thermal overload relays

mounting plate. Mount the plate on the posts, and then

2-37