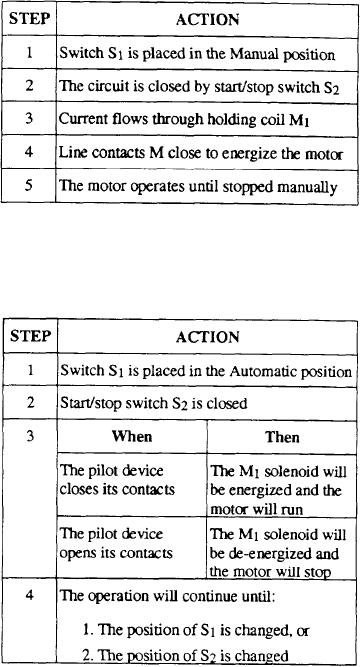

Table 2-9.--Manual Operation of Pilot Control Circuit

A) is normally used when liquid temperatures are to be

controlled. However, it may control air or gas

temperatures, provided the circulation around it is rapid

and the temperature changes at a slow rate.

The helical unit (fig. 2-40, view B) has been

specifically y designed for air and gas temperature control

circuits. To be most effective, the thermal unit must be

located at a point of unrestricted circulation so it can

"feel" the average temperature of the substance that is

to be controlled.

Some switches are stamped WIDE DIF-

FERENTIAL. They are adjusted in the same manner

The following table describes the sequence of

described for the regular controls. However, because of

events during the automatic operation of the circuit in

slight design changes, it is possible to get wider variation

table 2-10.

in differential settings.

Table 2-10.--Automatic Operation of Pilot Control Circuit

Maintenance

When adjusting temperature controls, allow several

minutes for the thermal unit to reach the temperatures

of the surrounding air, gas, or liquid before setting the

operating adjustments. After adjusting the operating

range of pressure or temperature controls, check the

operation through at least one complete cycle. If you

find variation from the desired operating values, go

through the entire procedure again and observe

operation through a complete cycle.

PILOT CONTROL DEVICES

A pilot is defined as a director or guide of another

thing (or person). You may be familiar with ship pilots,

pilot rudders, and pilot flames. In this text, a pilot is a

small device that controls a relative] y larger device or

mechanism, usually doing so by electrical means. The

previously described float switch and pressure-operated

switches are representative examples of such pilot

devices. Pilot devices are limited in their ability to

handle large currents and voltage required to operate

PROTECTIVE DEVICES

shipboard motors or power-handling units. Therefore,

Protective devices allow normal operation of

it is customary for a pilot device to actuate only a

circuits to continue unhampered. Once something goes

magnetic switch. The magnetic switch can be chosen

wrong in the circuit, protective devices will de-energize

with characteristics suitable for handling the desired

the circuit to minimize of prevent damage to equipment

amount of power in the motor circuit.

and ensure the safety of personnel. A thorough

knowledge of protective devices will help you isolate

Float switches used as pilot devices control the

troubles in circuits, find the cause of interruption, clear

pump operation through other controls. A typical

the trouble, and restore operation with minimum loss of

control circuit is shown in figure 2-38.

time.

Switch S 1 makes it possible to have either manual

or automatic operation of the motor-driven device.

MAGNETIC OVERLOAD RELAY

Table 2-9 describes the sequence of events when

A magnetic type of overload relay for a dc system

operating the pilot device control circuit (table 2-10)

is shown in figure 2-41. A pictorial view and a diagram

manually.

2-34