The operating (series) coil (6) is connected in series

turned Then, to lower the tripping current, raise the

with the protected circuit. Therefore, the load current

dashpot by turning it. This action raises the plunger

flows through the coil. If the circuit current rises above

further into the magnetic circuit of the relay so that a

normal because of overload conditions, it will cause an

lower current will trip the relay.

increase in the magnetic lines of flux about the coil. The

You can increase the current at which the relay trips

increased flux lifts the iron plunger (5) into the center

by turning the dashpot in a reverse direction. This action

of the coil and opens the contactor/contacts (9). This,

reduces the magnetic pull on the plunger and requires

in turn, causes the main contactor (not shown) to open,

and disconnects the motor or other device from the line.

more current to trip the relay. After the desired settings

An oil dashpot mechanism (1 and 2) is used to prevent

have been obtained, lower the indicating plate over the

the operation of the relay on motor starting current

hexagonal portion of the dashpot to again indicate the

surges.

tripping current and lock the dashpot in position.

If the relay does not have manual latching, a

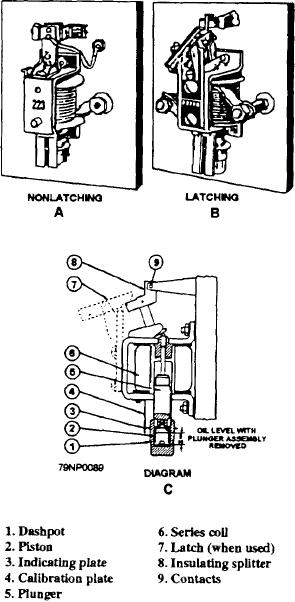

Figure 2-42 shows two magnetic types of ac

three-wire control is provided to give automatic reset

overload relays. View A is the nonlatching type, and

after an overload occurs. The manual-latch relay is

view B is the latching type. In view C the various

generally used with two-wire control. The latch (7)

components are identified

holds the contacts in the open position after an overload

has occurred and the circuits have been de-energized.

The operator must manually reset the overload relay at

the controller.

THERMAL OVERLOAD RELAY

The thermal type of overload relay (ac and dc) is

designed to open a circuit when excessive current causes

the heater coils to reach the temperature at which the

ratchet mechanism releases. The heater coils are rated

so that normal circuit current will not produce enough

heat to release the ratchet mechanism.

The essential operating parts of a de thermal

overload relay (fig. 2-43) are the two heater coils (4),

two solder tube assemblies (5), and control contacts (8).

Under normal conditions the splitter arm (7) (so called

because it splits the overload contacts) completes a

circuit with the contacts. The spring is then under

compression, and the operating arm (3) tends to rotate

the splitter arm out of the circuit. This action is

prevented by the ratchet assembly, which is held by the

solder film between the outer and inner part of the solder

tubes.

When current flows through the heater coils and

produces enough heat to melt the solder film, the inner

part of the solder tube assembly rotates and releases the

ratchet mechanism to open the control circuits. When

this happens, the circuit to the coil handling the power

contacts (not shown in fig. 2-43) opens and disconnects

the load. As soon as the load is disconnected, the heaters

cool, and the solder film hardens. When the hardening

is complete, the relay is ready to be reset with the reset

Figure 2-42.--Two ac overload relays.

button.

2-36