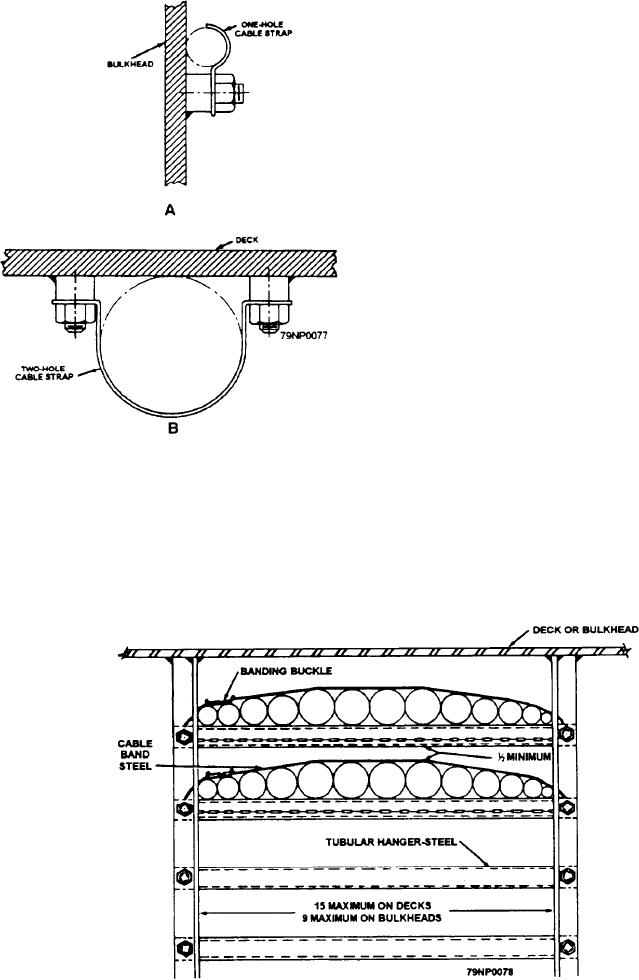

so forth. The one-hole cable strap (fig. 2-30, view A)

may be used for cables not exceeding five-eighths inch

in diameter. The two-hole strap (fig. 2-30, view B) may

be used for cables over five-eighths inch in diameter.

The spacing of simple cable supports, such as those

shown in figure 2-30, must not exceed 32 inches, center

to center.

Cable Rack

The cable rack is more complex than the single

cable strap. The cable rack consists of the cable hanger,

cable strap, and hanger support (fig. 2-31).

The banding material of the cable rack is 5/8 inch

wide. It may be made from zinc-coated steel,

corrosion-resistant steel, or aluminum, depending on the

requirements of the installation. For weather deck

installations, use corrosion-resistant steel with

copper-armored cables, zinc-coated steel with steel

armor, and aluminum with aluminum armor.

When applying banding material to the cable rack,

you should apply one turn of banding for a single cable

of less than 1 inch in diameter. Apply two turns of

banding for single cables of 1 inch or more in diameter

Figure 2-30.--Single cable strap application.

and for a row of cables. Apply three turns of banding

for partially loaded hangers where hanger width exceeds

Single Cable Strap

the width of a single cable or a single row of cable by

more than 1/2 inch.

The single cable strap (fig. 2-30) is the simplest

Cables must be supported so that the sag between

form of cable support. The cable strap is used to secure

supports, when practical, will not exceed 1 inch. Five

cables to bulkheads, decks, cable hangers, fixtures, and

Figure 2-31.--Cables installed in a cable rack.

2-28