stuffing tube, should have a minimum height of 9 inches

removed. The solid plug is inserted in place of the

and a maximum height of 18 inches. If the height

grommet, but the slip washers are left in the tube (fig.

exceeds 12 inches, a brace is necessary to ensure rigid

2-28, view B).

support. If the installation of kickpipes is required in

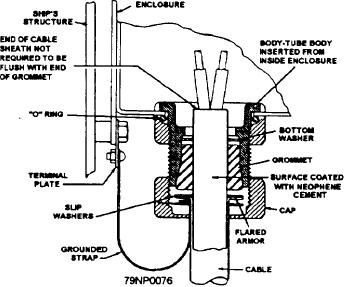

A grounded installation that provides for cable entry

nonwatertight decks, a conduit bushing may be used in

into an enclosure equipped with a nylon stuffing tube is

place of the stuffing tube.

shown in figure 2-29. This type of installation is

When three or more cables pass through a deck in a

required only when radio interference tests indicate that

single group, riser boxes must be used to provide

additional grounding is necessary within electronic

protection against mechanical damage. Stuffing tubes

spaces. In this case, the cable armor is flared and

are mounted in the top of riser boxes required for topside

trimmed to the outside diameter of the slip washers.

weather-deck applications. For cable passage through

One end of the ground strap, inserted through the cap

watertight decks inside a vessel, the riser box may cover

and one washer, is flared and trimmed to the outside

the stuffing tubes if it is fitted with an access plate of

diameter of the washers. Contact between the armor

expanded metal or perforated sheet metal.

and the strap is maintained by pressure of the capon the

slip washers and the rubber grommet.

Aboard ship, watertight integrity is vital. Just one

Wireways

improper cable installation could endanger the entire

ship. For example, if one THFA-4 cable (0.812 inch in

Before you install new cable, survey the area to see

diameter) were to be replaced by the newer LSTSGA-4

if there are spare cables in existing wireways and spare

cable (0.449 inch in diameter), but the fittings passing

stuffing tubes that can be used in the new installation.

through a watertight bulkhead were not changed to the

The cable run must meet the following criteria:

proper size, the result might be two flooded spaces if a

collision or enemy hit occurs.

Be located so that damage from battle will be

minimized

Deck Risers

Be located so physical and electrical interference

with other equipment and cables will be avoided

Where one or two cables pass through a deck in a

single group, kickpipes are provided to protect the

Be located so that maximum dissipation of

cables against mechanical damage. Steel pipes are used

internally generated heat will occur.

with steel decks, and aluminum pipes with aluminum

and wooden decks. Inside edges on the ends of the pipe

Where practical, you should route vital cables along

and the inside wall of the pipe must be free of burrs to

the inboard side of beams or other structural members

prevent chafing of the cable. Kickpipes, including the

to afford maximum protection against damage by flying

splinters or machine gun straffing. Only when

necessary, should cables be run on the exterior of the

deckhouse or similar structures above the main deck.

Avoid installing cable in locations subject to

excessive heat, if possible. Never install cables adjacent

to machinery, piping, or other hot surfaces having an

exposed surface temperature greater than 150F. In

general, cables should not be installed where they may

be subjected to excessive moisture.

CABLE SUPPORTS

To prevent unnecessary stress and strain on cables,

cable supports or straps are used. Types of cable

supports are the single cable strap, cable rack, and

Figure 2-29.--Nylon stuffing tube grounded installation.

modular cable supports.

2-27