This allows a single-size stuffing tube to be used for a

of equipment enclosures. However, top entry into these

variety of cable sizes, and makes it possible for nine

enclosures should be made dripproof through stuffing

sizes of nylon tubes to replace 23 sizes of aluminum,

tubes or cable clamps sealed with plastic sealer.

steel, and brass tubes.

Uses below and above the Main Deck

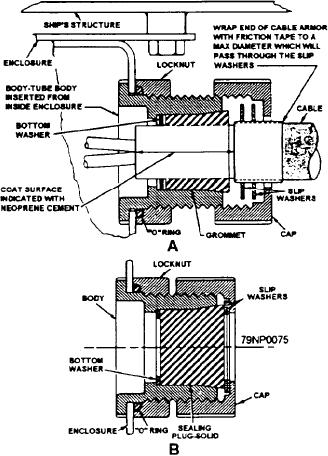

The nylon stuffing tube is available in two parts.

The body, O-ring, locknut, and cap comprise the tube;

Below the main deck, stuffing tubes are used to

and the rubber grommet, two slip washers, and one

penetrate the following areas:

bottom washer comprise the packing kit.

Watertight decks

A nylon stuffing tube that provides cable entry into

an equipment enclosure is applicable to both watertight

Watertight bulkheads

and nonwatertight enclosures (fig. 2-28, view A). Note

Watertight portions of bulkheads that are

that the tube body is inserted from inside the enclosure.

watertight only to a certain height

The end of the cable armor, which will pass through the

slip washers, is wrapped with friction tape to a

Above the main deck, stuffing tubes have the

maximum diameter. To ensure a watertight seal, one

following uses for cable penetrations:

coat of neoprene cement is applied to the inner surface

Watertight or airtight boundaries

of the rubber grommet and to the cable sheath where it

will contact the grommet. After the cement is applied,

Bulkheads designed to withstand a waterhead

the grommet is immediate y slipped onto the cable. You

Portions of the bulkhead below the height of the

must clean the paint from the surface of the cable sheath

before applying the cement.

sill or coaming of compartment accesses

Flametight or gastight or watertight bulkheads,

Sealing plugs are available for sealing nylon

stuffing tubes from which the cables have been

decks, or wiring trunks within turrets or gun

mounts

Structures subject to sprinkling

Construction

Stuffing tubes are made of nylon, steel, brass, or

aluminum alloys. Nylon tubes have very nearly

replaced metal tubes for cable entry to equipment

enclosures. Cable penetration of bulkheads and decks

are normally of metal because of their integrity during

fires. Stuffing tubes made of metal are normally used

for cable penetration of bulkheads and decks. Nylon

stuffing tubes melt and fail to act as a barrier during a

fire.

The nylon stuffing tube is lightweight,

positive-sealing, and noncorrosive. It requires only

minimum maintenance for the preservation of

watertight integrity. The watertight seal between the

entrance to the enclosure and the nylon body of the

stuffing tube is made with a neoprene O-ring, which is

compressed by a nylon locknut. A grommet-type,

neoprene packing is compressed by a nylon cap to

accomplish a watertight seal between the body of the

tube and the cable. Two slip washers act as compression

washers on the grommet as the nylon cap of the stuffing

tube is tightened. Grommets of the same external size,

Figure 2-28.--Representative nylon stuffing tube installations.

but with different sized holes for the cable, are available.

2-26