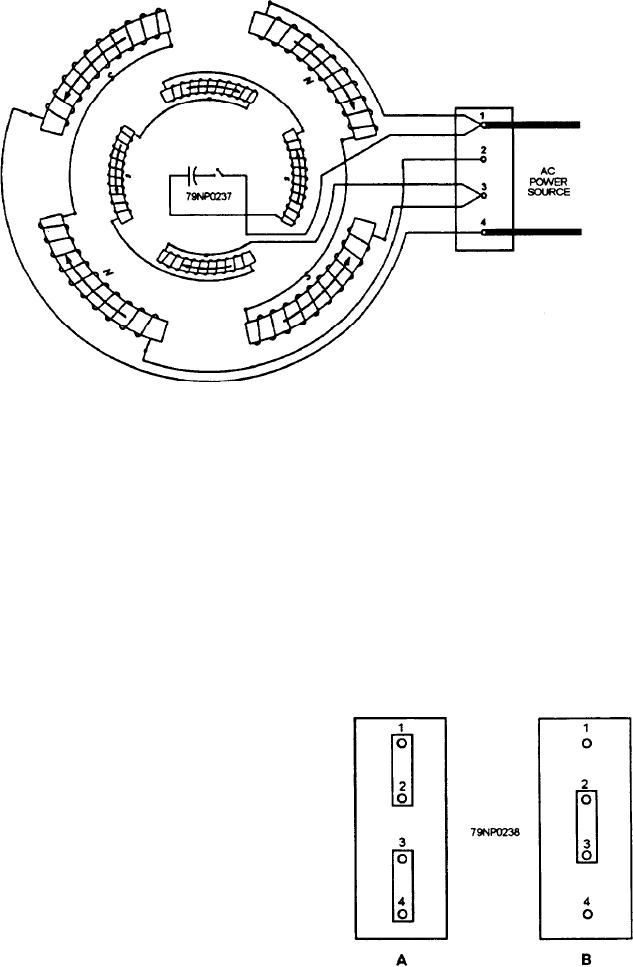

Figure 7-70.--Single-phase, capacitor-start, inductor-run motor diagram.

1. Inspect the motor for defects such as cracked end

SINGLE-PHASE (SPLIT-PHASE) AC

plates, a bent shaft, a broken or burned winding.

MOTOR REPAIR

2. Check the motor forbearing troubles.

There are many applications for single-phase

motors in the Navy. They are used in interior

3. Test the motor for grounds, opens, and shorts

communications equipment, refrigerators, fans,

(see armature and three-phase stator sections).

drinking fountains, portable blowers, portable tools, and

If rewinding is required, record the necessary data

many other applications. Single-phase motors are

on a single-phase motor data card (fig. 7-69).

considerably cheaper in fractional horsepower sizes; but

A single-phase motor connection is shown in figure

above 1 horsepower, the three-phase motors are less

7-70. When you connect the motor to a power source

expensive. The use of single-phase motors also

of 110 volts ac the motor run windings are connected

eliminates the need of running three-wire service to

in parallel by placing the two connecting bars as shown

supply small loads.

in figure 7-71, view A.

Single-phase motor failure is usually caused by the

starting winding burning out. The centrifugal switch

(fig. 7-68) cuts the starting winding out of the system

when the motor reaches about 75 percent of rated speed.

When the motor is overloaded, the speed decreases and

allows the centrifugal switch to energize the starting

windings. Then, the motor speeds up enough so that the

centrifugal switch opens the starting winding again.

This constant opening and closing of the starting

winding circuit can cause failure of the winding due to

excessive temperature.

Steps in analyzing motor troubles should proceed,

as previously mentioned, following a logical sequence

Figure 7-71.--Connecting bars. (A) Low voltage input; (B)

to determine what repairs are required for

High voltage input.

reconditioning the motor:

7-47