When you reconnect the motor to a power source of

coil. When coils are placed in stator slots, they can be

220 volts ac, the run windings must be connected in

wound in place by hand or wound in a coil winder on

forms, and then placed in the slots of the stator.

series by placing the two connecting bars as shown in

figure 7-71, view B.

Capacitors used with single-phase motors for

starting should be checked by means of a capacity tester.

By tracing through the two series and parallel

This also applies to the capacitor-start, capacitor-run

bar-connected circuits, you will note that the starting

type of motors.

winding operates on 110 volts regardless of a parallel

or series connection.

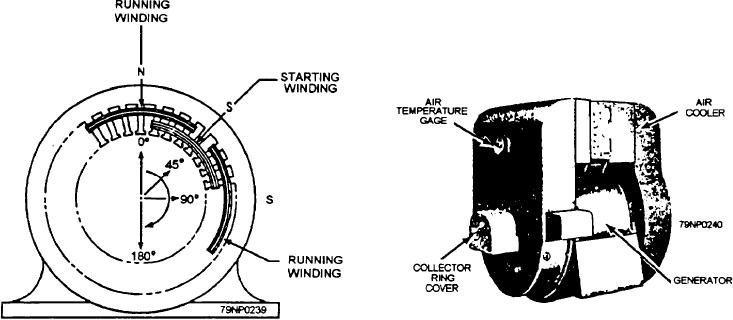

MOTOR AND GENERATOR AIR

Figure 7-72 is a diagram of a four-pole, split-phase

COOLERS

motor. The type of winding used on both the running

Some large electric motors and generators, such as

and starting windings is the spiral winding. The

difference between the two windings is their impedance

propulsion generators and motors, are equipped with

surface-type air coolers. In this system the air is

and position in the stator slots. The running winding has

circulated by fans on the rotor in a continuous path

a low resistance and a high reactance (because of many

through the machine windings and over the

turns of large wire), and the starting winding has a high

water-cooled tubes of the cooler. The ceder is of

resistance and a small reactance (being wound of small

double-tube construction (one tube inside another).

or high-resistance wire).

This minimizes the possibility of damage due to water

The running winding is placed in the bottom of the

leakage. I&location of the air cooler on a generator is

slots, and the starting winding is placed on top of the

shown in figure 7-73.

running winding. Both windings are energized in

The air and water sides of air cooler tubes must be

parallel at starting. The currents are out of phase with

kept as clean as possible because foreign deposits will

each other, and the combined effects produce a rotating

decrease heat transfer. When you are required to clean

field that starts the motor (some motors use capacitors

the air side of the tubes, the individual tube bundles may

for starting). When the motor has almost reached

be removed and washed with hot water or cleaned with

normal speed, the centrifugal switch opens the starting

a steam jet. The water side of cooler tubes must be

winding circuit, and the motor operates as a single-phase

cleaned following instructions contained in the NSTM,

induction motor.

chapter 254.

A pole for the running or the starting winding in a

When a leak between an inner tube and the tube

single-phase motor is made up of more than one coil.

sheet occurs, water will seep from the cooler head

These coils differ from each other in size and, depending

through the leaky joint into a leak-off compartment and

on the winding specifications, in the number of turns per

out the leakage drain. If a leak in an inner tube, water

will seep into slots in the outer tube where it is carried

to a leak-off compartment and out the leakage drain.

The leakage drain line is equipped to give a visual

indication of the presence of water in the line.

Figure 7-73.--Generator equipped with an ailr cooler.

Figure 7-72.--A four-pole, split-phase motor.

7-48