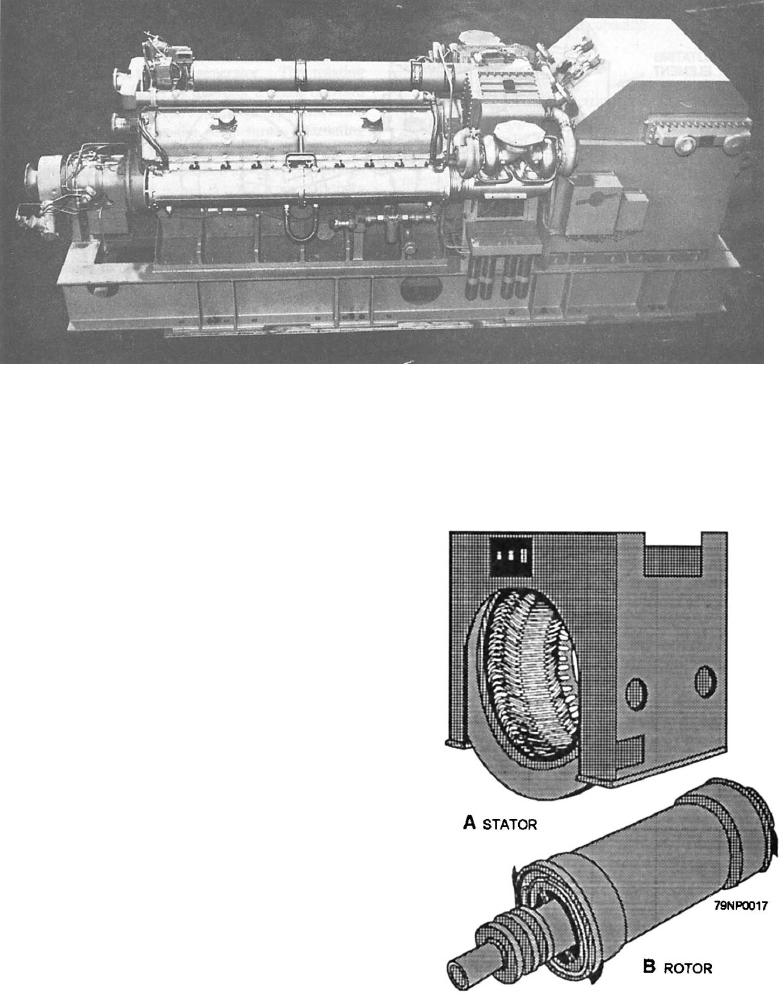

Figure 3-16.--Low-speed, engine-driven ac generator.

CONSTRUCTION AND OPERATION OF AC

only directs the paths of the circulating, air-cooling

GENERATOR SETS

currents, it also reduces windage noise.

Many of today's modern ship's utilize gas turbine

AC generator sets maybe divided into the following

units to provide power for propulsion and generating

two classes according to the speed of the generator:

1. Low speed, engine driven

2. High speed, turbine driven

The stator, or armature, of the revolving-field ac

generator is made of steel punchings called laminations.

The laminations of an ac generator stator form a steel

ring keyed or bolted to the inside circumference of a

steel frame. The inner surface of the laminated ring has

slots in which the stator winding is placed.

A low-speed, engine-driven ac generator (fig. 3-16)

has a large-diameter revolving field with many poles and

a stationary armature that is relatively short in axial

length. The stator contains the armature windings. The

rotor consists of salient poles, on which are mounted the

do field windings.

The high-speed, turbine-driven ac generator (fig. 3-

17) is connected to a turbine either directly or through

gears. The enclosed metal structure is a part of a forced

ventilation system that carries away the heat by

circulation of the air through the stator (fig. 3-17, view

A) and the rotor (fig. 3-17, view B). (The exciter is a

Figure 3-17.--High-speed, steam turbine-driven ac

separate unit and is not shown.) The enclosed stator not

generator.

3-14