addition, varnishing helps windings keep their form and

2. Coil side separators, which are placed on top of

coil sides as they are laid into slots to prevent

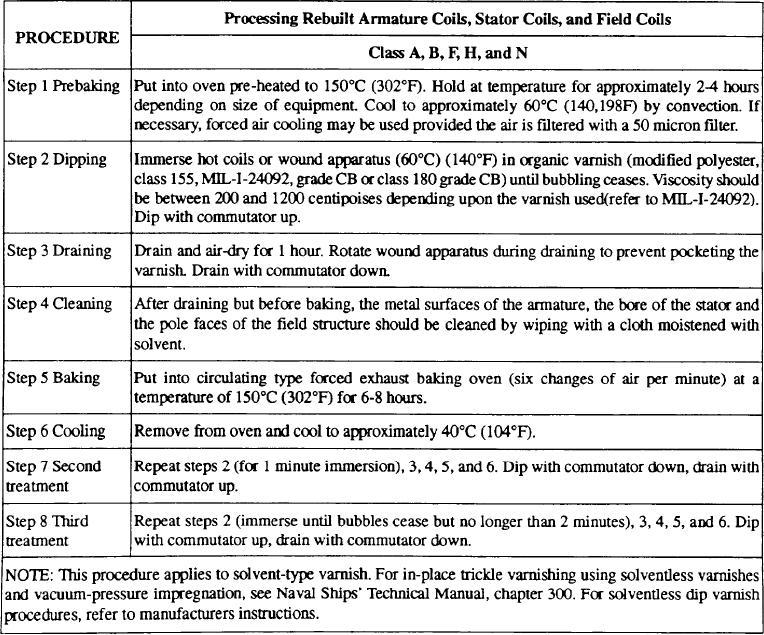

adds mechanical strength. The procedures for

two coil sides from touching one another within

varnishing new windings are given in table 7-7.

the same slot. May be made of flat silicon glass

Polyamide Paper

insulation or formed (curved) polyamide paper.

Before placing windings in a stripped stator or

3. Slot wedges, which are used to close up slots

armature the slots must be insulated to prevent current

once all coil sides are inserted. They may be

leakage to ground and to insulate the separate windings

made of flat silicon glass insulation or formed

from one another. Polyamide paper is available in

(curved) polyamide paper.

various thicknesses and dielectric strengths for this

4. Phase insulation, which is used to prevent the

purpose.

ends of adjacent coils from touching one

another. It is made of .007 inch polyamide

There are four types of paper insulation used in

paper.

winding.

ELECTRICAL TESTS

1. Slot insulation, which is used to separate the coil

sides in the slot from the laminations. Prepared

Electrical tests are performed on new windings to

ensure connections are proper and that workmanship is

from two 7 mil (0.007") pieces of polyamide.

Table 7-7.--Varnishing Procedures

7-32