vibrate noticeably and will cause a chattering noise.

HAND TOOLS

Larger armatures, which do not fit in an external

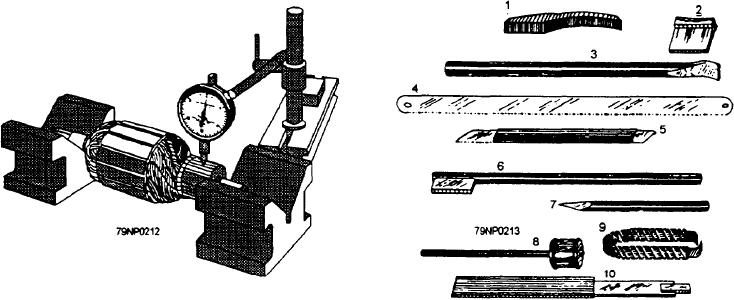

The hand tools used in rewinding armatures are

growler, may be checked by moving an internal growler

relatively few and simple. In fact, they are usually

over the outside surface of the armature. Internal

handmade by Electrician's Mates engaged in this work.

growlers are used primarily to check stator windings,

Figure 7-44 shows the following tools:

which will be covered later in this chapter under

three-phase stator repair.

1. A fiber from, which is used for shaping the coil

ends after the coils are placed in the slots

You should use a dial indicator for armature com-

mutator radius checks (fig. 7-43). Ensure commutators

2. A steel slot drift, or tamping tool, which is used

are not out-of-round more than 1 mil (0.001 inch).

for driving the coils to the bottom of partly

closed slots

REWINDING PROCEDURES

3. A lead lifter, which is used for lifting the coil

leads from the commutator risers

When tests or observations show that a piece of

rotating electrical machinery needs replacing and no

4. A hacksaw blade, which is used for removing

replacement is available, rewinding is necessary. The

the fiber wedges that hold the coils in the slots

process for rewinding a piece of rotating electrical gear

5. A handsaw, which is used for undercutting the

is basically the same for all types of machines. The

commutator mica between the segments

process can be divided into 9 key steps:

6. A wedge driver, which is used for driving the

1. Disassembly

fiber wedges out of the slots

2. Burning/stripping

7. A lead drift, which is used for cutting off the

3. Recording data

leads at the risers

4. Cleaning

8. A rotation indicator, which is used as an aid to

determine the proper connections of the

5. Insulating

windings

6. Winding

9. A wire scraper, which is used for removing the

7. Electrical testing

insulation from the ends of the coil leads

8. Varnishing

10. A wedge inserter, which is used for driving the

wedges into partly closed slots

9. Assembly

Figure 7-43.--Measuring commutator out-of-round with a

dial indicator.

Figure 7-44.--Armature rewinding hand tools.

7-30