After recording the initial winding data, perform a

compressed air. Dip the cleaned armature core in a

bar-to-bar test to determine if the winding is lap or wave;

varnish and bake according to the steps in table 7-7,

then record this information on the armature data card.

using a diluted varnish (20 percent varnish, 80 percent

Now you are ready to disconnect and remove the coils.

thinner) of the same type to be used after winding.

This treatment prevents the formation of oxides and

During this process, record the winding data that

forms a base for the adherence of the final varnish

was impossible to obtain before stripping the armature.

treatment.

Remove the banding wires by cutting them in two

places. If banding wires are not used, remove the

wedges in the slots. A simple means of removing the

Winding Armature Coils

wedges is to place a hacksaw blade, with the teeth down,

on the wedge. Tap the top of the blade to set the teeth

in the wedge, and then drive out the wedge by tapping

Formed coils are wound on a coil-winding machine

the end of the blade.

and pulled into the desired shape on the forming

machine. The shape of the coil is determined by the old

Next, unsolder the coil leads from the commutator

coil. The two wires forming the leads are taped with

and raise the top sides of the coils the distance of a coil

cotton or reinforced mica tape. The binder insulation,

throw (distance between the two halves of a coil). The

consisting of cotton or glass tape, is applied to the entire

bottom side of a coil is now accessible, and the other

coil surface.

coils can be removed. Exercise care to preserve at least

one of the coils in its original shape to use as a guide in

The coil is now sprayed with a clear, air-drying

forming the new coils. Next, record the wire size, the

varnish (grade CA), which conforms to Military

number of turns in a coil, and the type of insulation on

Specification MIL-V-1137. After the varnish has dried,

the coils and in the slots.

the coil ends are tinned to ensure a good connection to

the commutator.

The raise the coils without damaging the insulation,

use a small block of wood as a fulcrum resting on the

Preformed windings should be used on large

armature core and a steel bar or piece of wood as a lever.

armatures, but it is more practical to wind small

armatures by hand. End room is very limited, and

After the coil is partly raised, drive a tapered, fiber

wedge between the top and bottom coils within the slot

windings must be drawn up tightly to the armature core.

to finish raising the top coil from the slot. After stripping

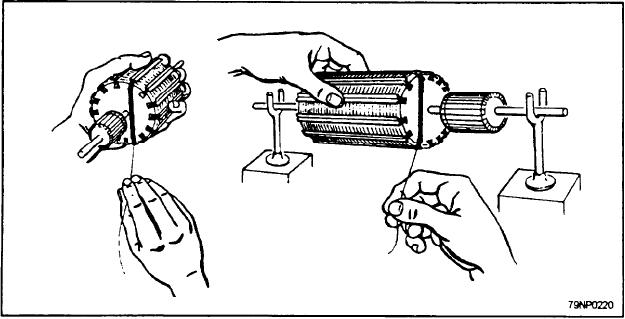

Figure 7-52 shows the methods of winding an armature

the armature, remove all dirt, grease, rust, and scale by

by hand. One armature in the figure is small enough to

sandblasting. File each slot to remove any burrs or

be hand held. The other, too heavy for this, rests on a

slivers, and clean the core thoroughly with dry,

support.

Figure 7-52.--Winding armatures by hand.

7-36