consist of many turns of tine wire and series and

of round wire. These coils have only a few turns that

commutating field coils consist of fewer turns of heavy

are wound in a single turn per layer.

wire.

A series coil wound (with ribbon copper) on edge is

illustrated in figure 7-54. It is more difficult to bend the

Shunt Coils

copper ribbon, but it has an advantage in that both

terminal leads protrude on opposite sides of the coil.

The equipment for rewinding shunt coils include a

Thus, the connections can be made very easily

lathe with a suitable faceplate, which can be turned at

compared to the strap-wound coils, which have one coil

any desired speed, and an adequate supply of the proper

end at the center and the other coil end at the outside of

size wire wound on a spool, which can be supported on

the. coil. The strap-wound construction requires leading

a shaft so that it is free to turn. Friction should be applied

the inside coil end over the turns of strap in the coil.

to the spool to provide tension on the wire. Secure a coil

form having the exact inside dimensions of the coil to

After the winding is completed, the coil is tested

electrically for continuity and shorted turns. It is then

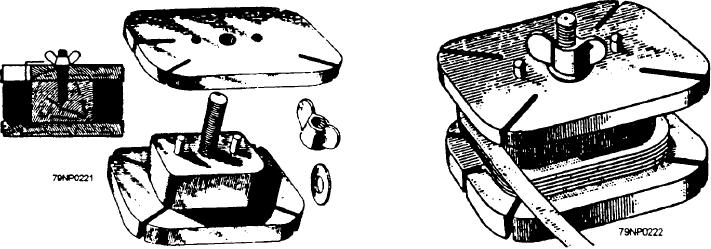

the lathe or faceplate. The form for shaped field coils

prebaked, varnished, and tested for polarity, grounds,

can be made from a block of wood shaped exactly to the

opens, and shorts, as described previously, at each stage

required size and provided with flanged ends to hold the

in turn.

wire in place (fig. 7-53). One of the flanges should be

removable so that the finished coil can be taken from the

forming block.

Testing Field Coils

The wire is wound from the spool onto the forming

block for the required number of turns. The turns must

Before installing a new or repaired coil, test it for

be evenly spaced, one against the other, until the

winding procedure is completed. The turns of the

shorts, opens, and grounds, and determine its polarity.

completed coil are secured by tape, and the wire leading

The same precautions that were observed during

to the spool is cut, leaving sufficient length to make the

removal of the coil must be observed when installing it.

external connections. The completed coil must be

All of the shims originally removed from the pole piece

must be in position when it is replaced. With the coil

checked electrically for continuity and for shorted turns.

positioned in the machine, it should be temporarily

The coil is now prebaked and varnish treated as

connected to the other coils in the field circuit and a

specified in table 7-7. When varnish-treated, the

compass and battery again used to check its polarity.

finished field coil should withstand a high-potential test

For this test, connect the battery to the proper field leads,

of twice the rated excitation voltage plus 1,000 volts.

and check the polarity of all the coils with the compass

(fig. 7-55). Adjacent poles must be of oppsite polarity.

Series and Commutating Coils

If necessary, the polarity of the new coil can be reversed

by reversing the leads. When the polarity is correct, the

Series and commutating field coils are frequently

coil is connected, and the pole-piece bolts are tightened.

wound with strap (rectangular) or ribbon copper instead

Air gaps should be measured to ensure uniformity.

Figure 7-53.--Coil form for field coils.

Figure 7-54.--Edge wound series coil.

7-38