ELECTRONIC CONTROLLED

the elevator. Reversing the direction of rotation of the

ELEVATORS

pilot motor reverses the direction of movement of the

control piston of the pump. This allows the elevator to

be moved in the opposite direction.

Elevators installed on some new naval ships use

In another electric-hydraulic system, the pilot motor

static controls (no meting parts). In these elevators,

is a dc motor. The speed of the motor is varied by a

electronic devices perform the functions of relays,

rheostat-type control that gives an infinite number of

contractors, and limit switches.

platform speeds. These speeds range from

approximately 3 to 90 feet per minute. In installations

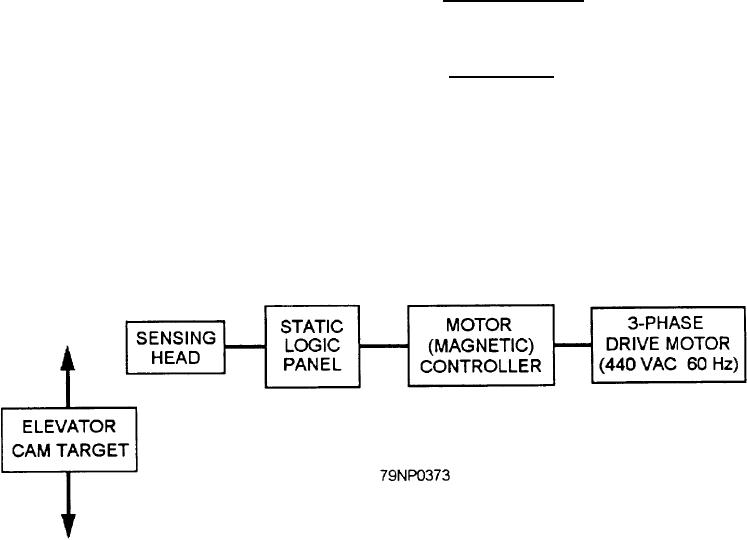

The electronic controlled elevator system

of this type, a rheostat control is provided on the

components (fig. 5-25) include the elevator cam target,

the sensing heads, the static logic panels, the motor

platform, and a duplicate control is provided in the

elevator machinery room.

(magnetic) controller, and a three-phase drive motor.

These system components function as follows:

Several methods are used for stroking the pump for

emergency operation two of which are as follows:

The elevator cam targets are steel cams or vanes,

mounted on the elevator platform to actuate the sensing

1. Declutching the "follow-up" control system

heads.

from the control stroking unit and manually holding in

a pushbutton. This action releases the electric motor

The sensing heads are mounted up and down

brake to free the machinery. A handwheel maybe used

the elevator trunk bulkhead. They are used for

to stroke the pump.

many elevator functions, such as slowing and

stopping, high-speed up and down stops, governing

2. Rotate the pilot motor armature by attaching a

overspeed, preventing overtravel, and door interlock

handwheel to an extension on the armature shaft, thus

functions.

stroking the pump.

Figure 5-25.--Block diagram of electronic controlled elevator system.

5-43