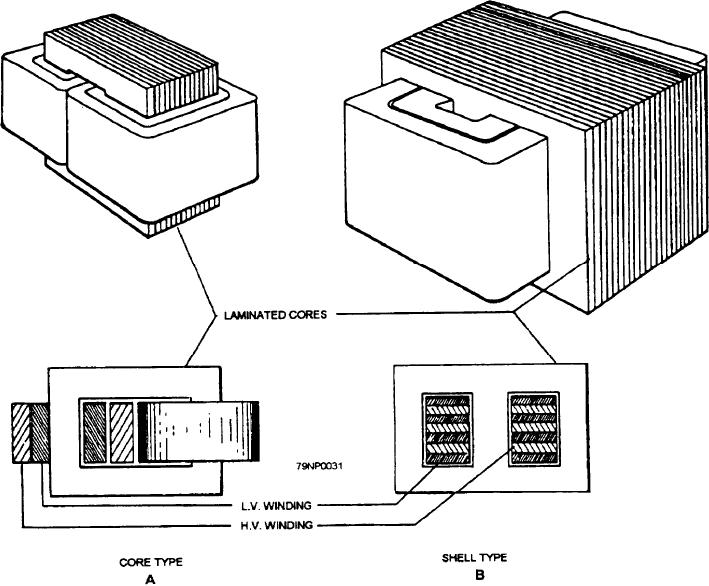

Figure 3-31.--Types transformer construction.

drop, half of each winding is placed on each leg of the

between magnetic particles as they are rotated through

core. The windings may be cylindrical in form and

each cycle of magnetization, are minimized by the use

of a special grade of heat-treated, grain-oriented,

placed one inside the other with the necessary

silicon-steel laminations.

insulation, as shown in figure 3-31, view A. The

low-voltage winding is placed with a large part of its

In the core type of transformer, copper windings

surface area next to the core, and the high-voltage

surround the laminated iron core. In the shell type of

transformer, an iron core surrounds the copper

winding is placed outside the low-voltage winding in

windings. Distribution transformers are generally of the

order to reduce the insulation requirements of the two

core type, whereas some of the largest power

windings. If the high-voltage winding were placed next

transformers are of the shell type.

to the core, two layers of high-voltage insulation would

If the windings of a core-type transformer were

be required, one next to the core and the other between

placed on separate legs of the core, a relatively large

the two windings.

amount of the flux produced by the primary winding

In another method, the windings are built up in thin,

would fail to link the secondary winding and a large

flat sections called pancake coils. These pancake coils

leakage flux would result. The effect of the leakage flux

are sandwiched together with the required insulation

would be to increase the leakage reactance drop, IXL, in

between them, as shown in figure 3-31, view B.

both windings. To reduce the leakage flux and reactance

3-25