the thermostatic assembly is inoperable. Corrective

maintenance of the regulating valve consists of

inspecting the valve for leaks and for freedom of stem

movement, adjusting the set point at which the valve

regulates, renewing the thermostatic assembly, and

cleaning and restoring valve parts. Any time that you

remove a valve, you should center punch a dot code on

each piece to ensure that the valve and piping are

installed in the original configuration. The three-way

valve can be turned around, and the problem could go

unnoticed until you try to align the temperature

regulation of the cooling system. There are individual

manuals for the temperature-regulating valves and they

should be closely followed. For example, if you remove

the top of the thermostatic assembly without chilling the

temperature probe, the bellows will expand and rupture,

making the unit worthless. To verify that the

thermostatic assembly has failed, close valves upstream

and downstream of the thermostatic bulb, drain the unit

below the location of the bulb, and remove the bulb from

its well. Place the bulb in a suitable vessel and observe

the valve stroke while the bulb is alternately heated with

hot water and cooled with cold water. If the valve

thermostatic assembly does not respond, it has lost its

thermostatic charge, and a new unit must be installed.

FLOW REGULATORS

You will encounter many different types and sizes

of flow regulating devices used in both the primary and

secondary cooling systems. They are used to reduce the

pressure or the flow of coolant through a cooling system.

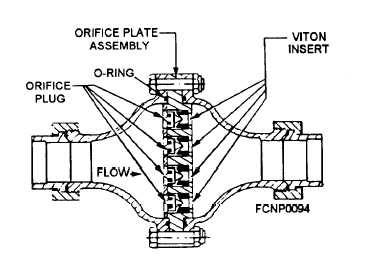

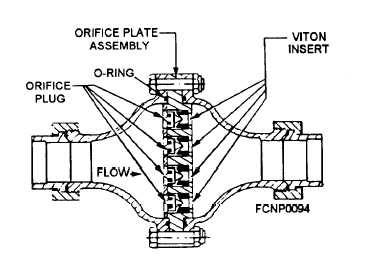

The orifice plate is found primarily in the seawater

cooling system.

It is the simplest design of a flow

regulating device, consisting of a steel plate with a hole

in it. With constant known seawater pressure and with

a given hole size, the volume of water through the device

can be determined. The use of an orifice plate is limited

to where the input water pressure is essential y constant,

such as the ship’s firemain. The orifice plate is normally

installed between two pieces of flanged pipes upstream

from the heat exchanger as shown in figures 1-6 and 1-7.

This will reduce the ship’s firemain pressure below the

pressure in the secondary cooling system. As we have

indicated earlier, should one of the heat exchanger tubes

fail, the seawater pressure is lower than the distilled

water pressure; therefore, it would not contaminate the

secondary cooling system. The secondary cooling

system would force distilled water into the primary

cooling system. A ruptured heat exchanger tube or a bad

single tube sheet in a heat exchanger would give no

visual indication of water loss except for the indication

on the expansion tank sight glass. To stabilize the flow

of seawater and to prevent jet erosion of the heat

exchanger and associated piping, the orifice plate should

be installed with at least 15 pipe diameters of straight

pipe upstream from the heat exchanger. When there is

a drop in the heat exchanger primary input pressure and

the seawater supply pressure has not changed, you

should first check the duplex strainer differential

pressure gauge to ensure that the duplex strainer is clean.

Then the orifice plate should be inspected for deposits

or particles that could restrict the seawater flow. You

should also inspect the orifice plate for erosion damage

of the hole diameter.

The orifice plate should be

replaced when there is an increased flow of seawater to

the point that it could damage the heat exchanger. Never

use the seawater valves to throttle (partially closed) the

flow of seawater in the primary cooling system, because

the seawater will erode the internal parts of the valve.

The damage to the valve would require extensive repair

or replacement, because the valve would no longer close

properly.

When used with the chilled-water system, the

constant flow regulator (variable orifice, fig. 1-17) is

installed downstream from the heat exchanger. This

restricts the flow from the heat exchanger and keeps the

heat exchanger fully submerged for greater efficiency

(heat transfer). This type of flow regulator is not used

in the seawater system because the internal parts would

easily become fouled with marine growth and deposits.

The operation is dependent on the movement of the

orifice plugs (neoprene) to regulate the flow of water.

Another type of flow-regulator valve (equipment

flow) used primarily with electronic equipment to

regulate the flow of distilled water through the

Figure 1-17.-Constant flow regulator.

1-15