sealed dome and the outlet line fluid. When outlet line

pressure drops below dome pressure, the diaphragm

moves out slightly and pushes the main valve open.

This allows inlet line gas to flow through the valve until

outlet line pressure builds up enough to balance the

dome pressure. Then, the diaphragm moves back to

throttle or closes the main valve so that dome and outlet

pressures always remain in balance.

Any change in dome pressure causes a

corresponding change in outlet line pressure. When the

dome is completely vented, the main valve shuts off

bubble tight.

Any trouble with the pressure regulator can usually

be traced to the valve and valve seat, or to the diaphragm

and O-rings being worn or deteriorated.

Dehydrator

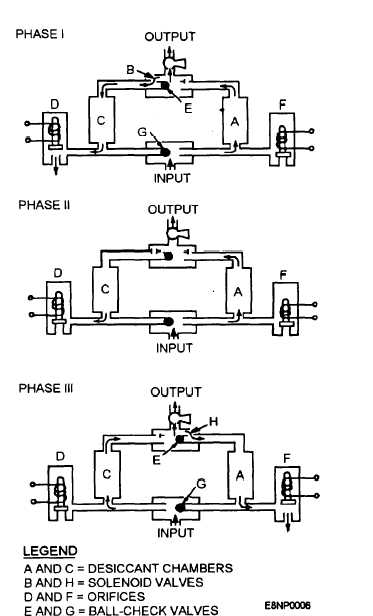

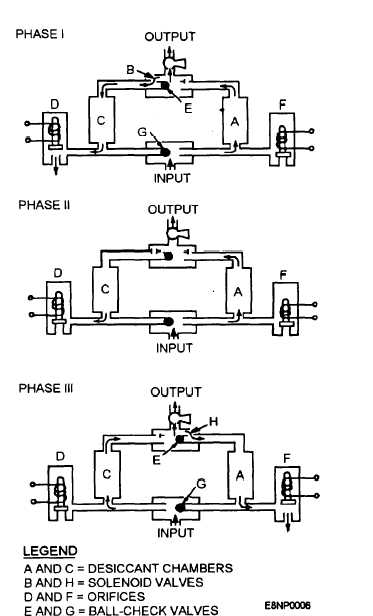

The dehydrator (fig. 2-5) consists of two desiccant

chambers filled with desiccant in the form of small

spheres. The desiccant chambers are supported by the

manifold, and they are connected to the manifold by

internal air passages. A pair of two-way solenoid valves

are attached to the bottom side of the manifold.

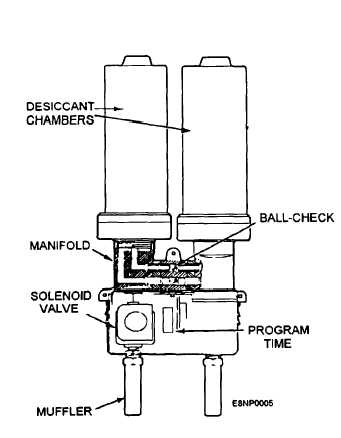

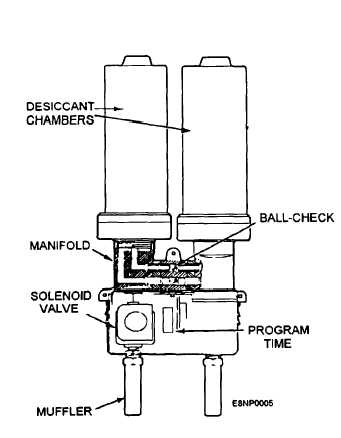

The program timer controls the operation of the two

solenoid valves. In one 60-second period, each solenoid

valve is open for 22 seconds and closed for 38 seconds.

The timing for the solenoid valves is such that both

valves are closed for two 8-second dwell phases. One

complete cycle takes place in each desiccant chamber

every 60 seconds.

Dry air is needed for reactivation of the desiccant

chambers. A small quantity of dry air (figs. 2-5 and 2-6,

phase I) is bypassed around the ball-check valve by a

Figure 2-5.—Dehydrator.

Figure 2-6.—Dehydrator operating cycle.

2-7