as adsorption There is a difference between absorption

and adsorption.

Absorption takes place in the telltale oil filter when

it removes oil by soaking it up as a liquid (the same way

that a sponge absorbs liquid water into its interior pores).

Adsorption is a surface and a molecular

phenomenon. Mobile gaseous and liquid atoms or

molecules are attracted to the surface of any solid

because of unbalanced forces existing at the surface.

Good absorbents are those that present large surfaces

per unit and have high attractive forces. One cubic inch

of the adsorbent material used in this dryer has an

adsorbent area greater than the area of two football

fields.

The wet air passes through chambers filled with a

molecular sieve type of desiccant, or adsorbing material.

Vapor molecules are left behind on the desiccant and the

air emerges clean and dry.

The dehydrator has two such chambers through

which the air passes alternately. While one chamber is

removing vapor from the air, a small portion of the dried

air is routed through the second chamber to purge it of

all collected vapors and to prepare it to do the drying

during the next half cycle.

The reactivation of the desiccant is completely

automatic, and unless slugs of entrained water or oil are

permitted to enter the desiccant chambers, the material

should not be replaced except at major overhaul. The

fluid separator and the telltale oil filter, located

upstream, prevent slugs of liquid from reaching the

desiccant if they are kept in good operating condition.

The dust filter, located downstream from the

dehydrator, removes any desiccant or other dust

particles that might otherwise be carried along in the dry

airstream. At the outlet of the drier unit, a flow limiter

is used to prevent the electronic equipment from

exceeding the capacity of the dryer. In normal

operation, the flowmeter has no effect. However,

should an air line or waveguide downstream from the

dryer be opened, the flow limiter would prevent an

excessive airflow beyond the capability of the dryer.

DRYER COMPONENTS

In figure 2-1, the placement of the individual

components is shown for a typical dryer. This is the

order that you should expect to see them. The air dryer

is a very reliable piece of equipment and with proper

PM can give you years of service.

The operation of the dryer can be bypassed by

changing the selector valve. With the selector valve in

the position as shown, all air is routed through the dryer.

Starting at the inlet, the individual operation of each

major component will be discussed in depth. Let’s

begin with the fluid separator and its dump trap.

Fluid Separator and Dump Trap

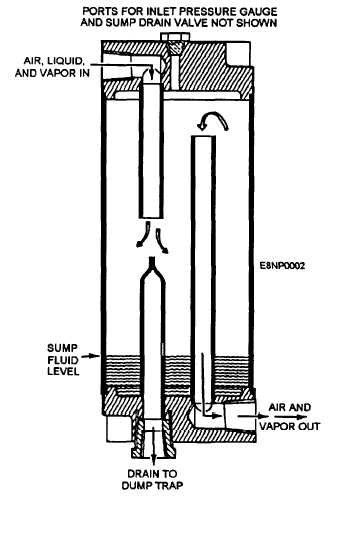

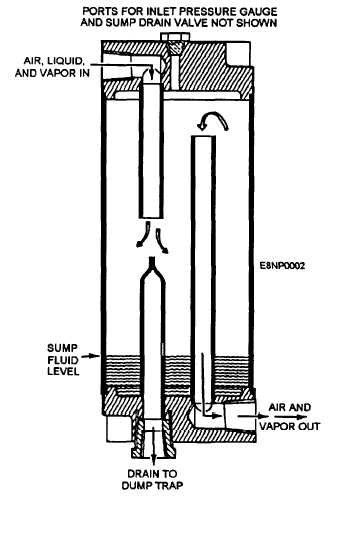

The fluid separator and dump trap consist of two

interconnected assemblies, the separator and the

automatic trap, connected together as shown in figure

2-2. The separator itself is a welded metal tank within

Figure 2-2.—Fluid separator.

2-4