the 802 Recall List to the 2L instead of hand

scribing it.)

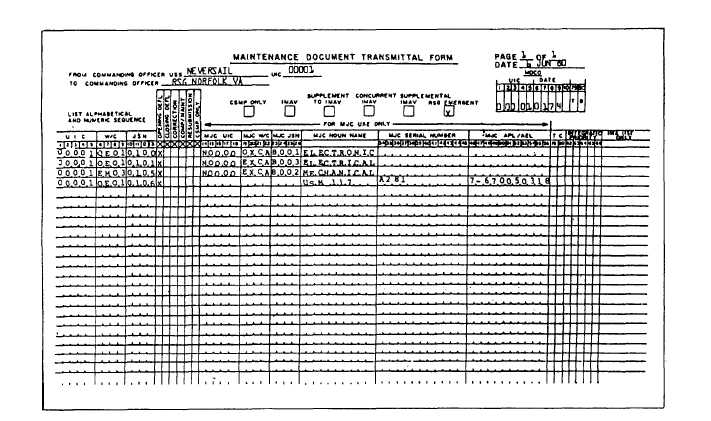

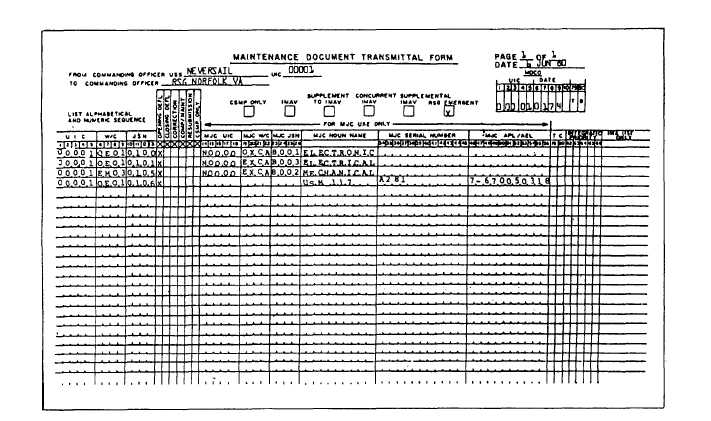

c. Maintenance Document Transmittal Form

(MDTF) (fig. 7-15)

Note: The type of request documents and

procedures may differ depending on TYCOMs’

guidelines.

7. Submit the paperwork to the appropriate activity

for items to be calibrated.

8. When you are notified of the activity or activities

designated to repair and/or calibrate your test

equipment, prepare the equipment for shipment.

Be sure to take adequate precautions (including

shock and environmental protection) to prevent

damage in transit. All test equipment will require

a METER card before it will be accepted at the

calibration or repair lab.

9. Remember to pickup the equipment when the

work has been completed. Do your part in the

coordinating of requests, deliveries, provision of

requested materials, follow-up, and pickup. If

you do your part and complete paper work

accurately, you should have the excellent test

equipment calibration package and service you

need to keep your systems and equipment

optimum condition.

Calibration Status Indication

The Navy calibration program has a series

in

of

distinctive labels and tags for indicating the calibration

or serviceability status of all Navy test and measuring

equipment. All calibration personnel and equipment

users should be familiar with each label and tag and its

meaning. Labels of different nomenclature, color

combinations, and shapes have been designed to help

users identify the calibration status. These labels and

tags are used by all participants in the Navy METCAL

program and must be affixed to all Navy standards and

test and measuring equipment. NAVAIR 17-35MTL-1,

Metrology Requirements List (METRL), lists Navy

calibration procedures and intervals for all standards

and test and measuring equipment. Only equipment

actually used for quantitative measurements requires

calibration.

MAINTENANCE

Test equipment requires the same two types of

maintenance (preventive and corrective) you are

Figure 7-15.-Maintenance Document Transmittal Form.

7-16