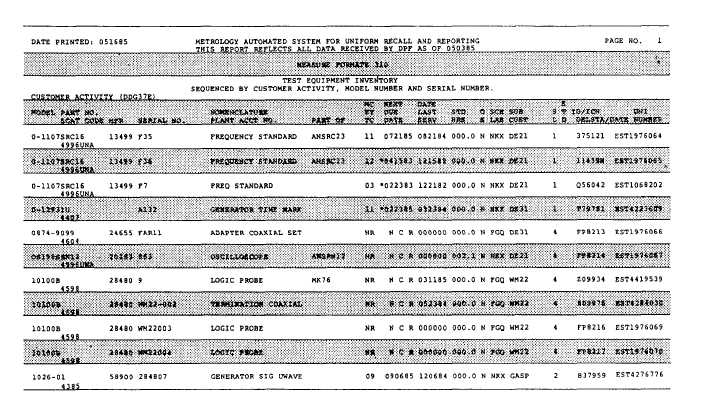

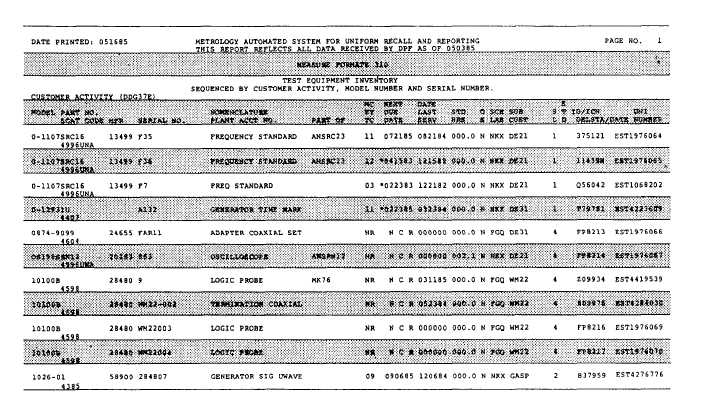

Figure 7-12.-MEASURE Format 310.

4. If changes in equipment status are not reflected

on the new monthly Format 310 within 60 days

of the transaction date, resubmit necessary

MEASURE METER cards (hand scribed) to

correct the discrepancy, or contact the Readiness

Support Group (RSG) (Atlantic Fleet) or the

Maintenance Coordinating Center (MCC)

MEASURE coordinator for assistance.

Requesting Calibration

If you know and follow the detailed procedures

outlined by your TYCOM, METCAL group, and area

MOCC for calibration of test equipment, you will

have serviced and calibrated test equipment available

when you need it. You can find flow charts and area

charts for calibration requests of the Atlantic and

Pacific Fleets in the Electronic Test Equipment

Calibration Program Indoctrination Handbook,

NAVMAT P-9491.

The following steps for requesting calibration are

general, but they should apply in most cases:

1. Read and familiarize yourself with the

instructions concerning test equipment

7-13

2.

3.

4.

5.

calibration procedures set forth in your TYCOM

maintenance manual, and the MEASURE Users

Manual.

Use MEASURE products to determine the

calibration due dates.

For items scheduled for calibration or items to

be calibrated, perform MIP T-1, MRC R-1.

If an item does not checkout with T-1 and R-1,

tag the equipment and note the malfunction.

Either repair the inoperable equipment

yourself or have your technicians repair it.

Calibration activities are not required to

accept equipment that is not in an operable

condition. If you are unable to repair the

equipment, send it to a repair facility

accompanied by a job order or work request

specifying exactly what is wrong.

If your ship has a field calibration activity (FCA)

on board, perform calibration on equipment

within your calibration package capability. Type

commanders stress that calibration must be done

at the lowest level and that it be closely

monitored.