10-18) with the value of coil settings, installation

is used to connect sections of cable. In some cases,

information, and a log section showing the details of

splicing is used instead of through boxes.

the action taken on the ship's degaussing system.

A wire diagram of the connections in the box is

The folder is prepared by degaussing range

pasted on the inside of the cover and coated with varnish

personnel when the ship's degaussing system is initially

or shellac. The wiring diagram for connection boxes

calibrated.

should (1) designate the conductors that may be

reversed without reversing the other loops, (2) indicate

the arrangement of parallel circuits so equal changes can

PREVENTIVE MAINTENANCE

be made in all parallel circuits when such changes are

Preventive maintenance is extensive for automatic

required, and (3) show the spare conductors. Spare

degaussing systems. The degaussing switchboards and

conductors should be secured to connection terminals in

the connection boxes and should not form a closed or

remote panels require frequent cleaning and inspection

as they are sensitive to heat and dirt. The removal of

continuous circuit. All conductors in a connection box

dirt and dust from automatic degaussing control

should be 1 1/2 times the length required to reach the

farthest terminal within the box. Connection boxes

equipment allows the natural flow of air around the

should also have drain plugs accessible to provide for

components for heat dissipation. Use of a vacuum

periodic removal of accumulated moisture from the

cleaner or bellows is a safe way to remove dust or dirt.

boxes.

Do not use compressed air.

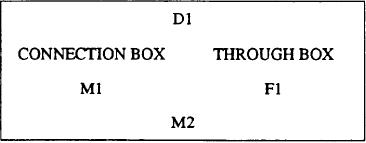

Connection and through boxes have

Check the connection or through boxes for

moisture. Drain plugs are installed in the bottom of

IDENTIFICATION PLATES that include degaussing

box numbers (such as D1 and D2), connection box

connection or through boxes to help you accomplish

and/or through boxes as applicable, and coil and loop

your inspection. When you notice moisture in a box

designations (such as Ml, M2, and F12).

during your inspection, leave it open to dry out. At the

same time, check the box cover gasket for deterioration,

and replace it if necessary.

When performing any preventive or corrective

maintenance on AUTODEG, observe standard

electrical safety precautions.

For additional information on degaussing systems,

refer to the Naval Ships' Technical Manual, chapters

300 and 475, and the manufacturers' instruction books.

This sample identified the No. 1 degaussing box serving

as a connection box for the M1 and M2 loops and as a

SUMMARY

through box for the F1 loop.

In this chapter, we have discussed the degaussing

systems installed aboard ships of the Navy. After

DEGAUSSING FOLDER

studying the information, you should have a better

The degaussing folder is an official ship's log. It

understanding of the earth's magnetic field, ship's

contains information on the magnetic treatment of the

magnetic fields, degaussing coils, ranging procedures,

ship, instructions for operating the shipboard

operation of various types of systems, and cable

degaussing system, degaussing charts (figs. 10-17 and

markings for degaussing installations.

10-19