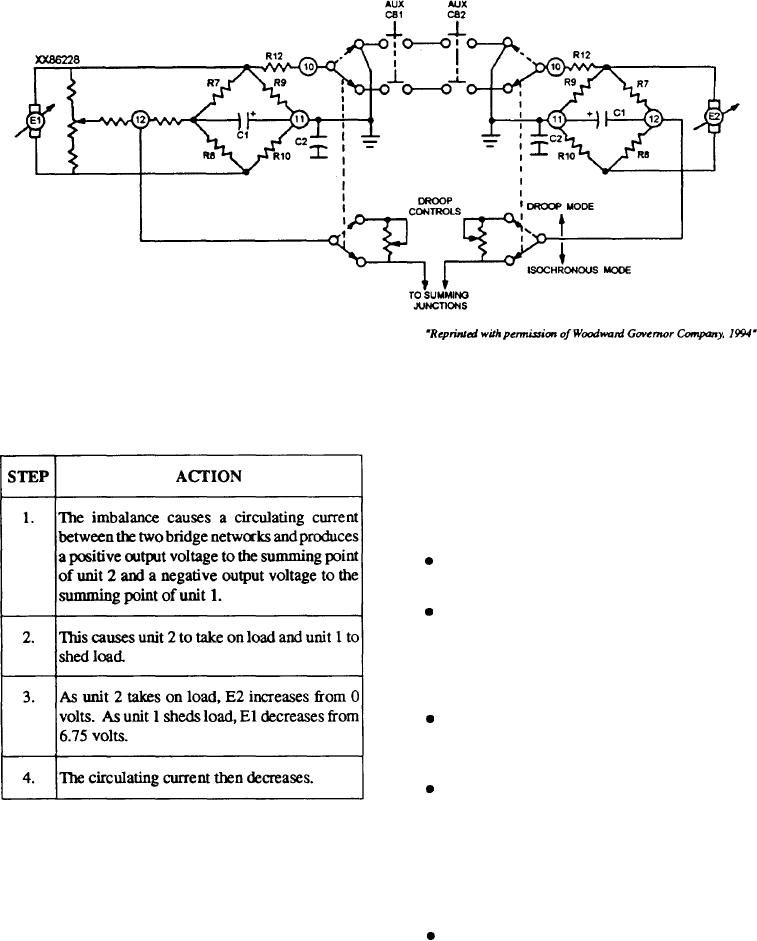

Figure 9-23.--Basic load sensor, parallel unit configuration.

MAINTENANCE

conditions. This condition exists at the moment of

paralleling, causing an electrical imbalance between the

Maintenance for the 2301 electric governor should

two load sensor bridge networks.

be conducted on a regular basis. The first step in the

procedure is to look for any obvious physical defects.

Missing, loose, or damaged electrical or mechanical

connections often result in more serious maintenance

problems if not corrected. Other maintenance

suggestions are as follows:

Transformers. Inspect all transformers for loose

or broken terminals. Check all mounting hardware.

Controls. Inspect all controls for loose mounting,

damaged wipers, or contacts and smoothness of

operation. Do not disturb the setting of a

screwdriver-adjusted control unless it is suspected of

being faulty.

Terminal blocks. Inspect all terminal blocks for

cracks, chips, or loose mounting hardware. Check all

wiring terminals for loose wires or lugs.

Printed circuit boards. Inspect printed circuit

boards for secure mounting and proper location in the

unit. It is not advisable to remove circuit boards for the

This continues until E1 equals E2 (4.5 volts) and

sole purpose of inspecting them for physical damage.

both generators share the load proportionally. Unit 1 is

Components mounted on printed circuit boards should

producing 50 kW, and unit 2 is producing 25 kW for a

be checked for secure mounting and poor electrical

total power of 75 kW.

connections.

The load sensors are only active during unequal

Wiring. Inspect all wiring for frayed or burned

had changes when a circulating current develops

leads. Insure that insulating sleeves are in place. Check

between the bridge networks. During an unequal

for loose or broken lacing in harnesses.

change, the bridge networks are electrical y unbalanced,

and the action is always toward proportional load

When power is secured, dust and foreign matter can

sharing.

be removed by brushing with a clean dry brush. Large

9-31