remove the armor (if installed) and impervious sheath,

trim the cable, and finish the end.

1. Determine the correct length by using the

following procedure:

Form the cable run from the last cable support

to the equipment by hand. Allow sufficient slack and

bend radius to permit repairs without renewal of the

cable.

Carefully estimate where the armor, if

applicable, on the cable will have to be cut to fit the

stuffing tube (or connector) and mark the location with

apiece of friction tape. Besides serving as a marker, the

tape will prevent unraveling and hold the armor in place

during cutting operations.

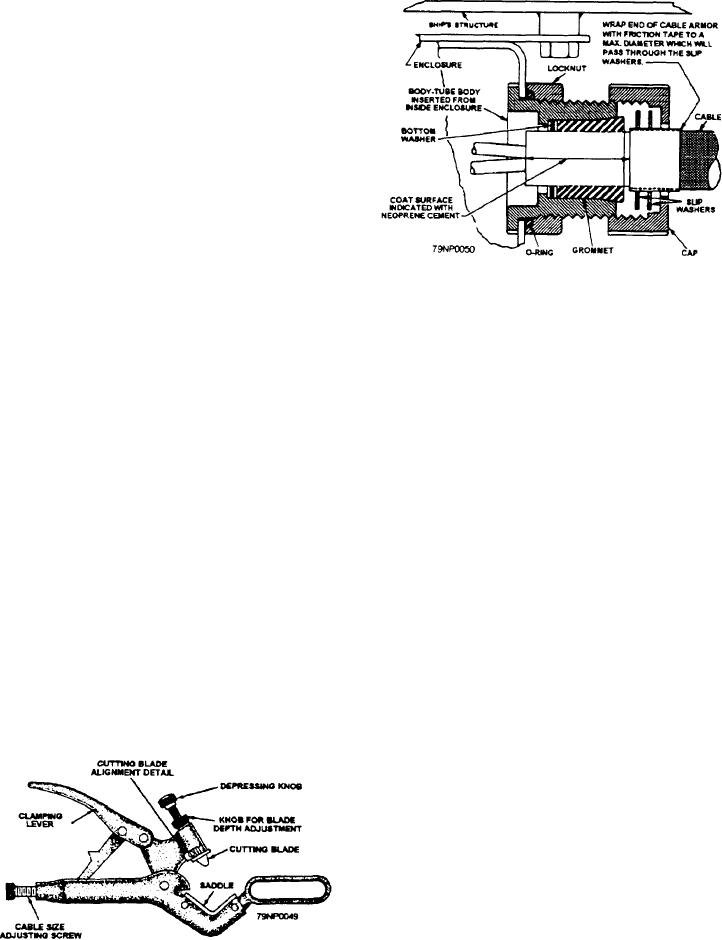

Figure 24.--Representative nylon stuffing tube installations.

Determine the length of the cable inside the

equipment, using the friction tape as a starting point.

the armor terminates. Use the cable stripper for this job.

Whether the conductors go directly to a connection or

Do not take a deep cut because the conductor insulation

form a laced cable with breakoffs, carefully estimate the

can be easily damaged. Flexing the cable will help

length of the longest conductor. Then add

separate the sheath after the cut has been made. Clean

approximately 2 1/2 times its length, and mark this

any paint from the surface of the remaining impervious

position with friction tape. The extra cable length will

sheath exposed by the removal of the armor (this paint

allow for mistakes in attaching terminal lugs and

will conduct electricity).

possible rerouting of the conductors inside the

equipment. You now know the length of the cable and

4. Once the sheath has been removed, trim the

can cut it.

cable filler with a pair of diagonal cutters.

2. Next the armor, if installed, must be removed.

5. There are several methods for finishing and

Use a cable stripper of the type shown in figure 2-3. Be

protecting cable.

careful not to cut or puncture the cable sheath where the

The proper method for finishing and

sheath will contact the rubber grommet of the nylon

stuffing tube (fig. 2-4). The uses and construction of

protecting cable ends not requiring end sealing is shown

stuffing tubes will be described later in this chapter.

in figure 2-5. For cables entering enclosed equipment

(such as connection boxes, outlet boxes, fixtures, etc.),

3. Remove the impervious sheath, starting a

use the method shown in figure 2-5, view A.

distance of at least 1 1/4 inches (or as necessary to fit

the requirements of the nylon stuffing tube) from where

An alternate method (when synthetic resin

tubing is not readily obtainable) is to apply a coat of

air-drying insulation varnish to the insulation of each

conductor as well as to the crotch of the cable. The end

of the insulation on each conductor is reinforced and

served with treated glass cord, colored to indicate proper

phase marking.

For watertight cables entering open

equipment (such as switchboards), use the method

shown in figure 2-5, view B. An alternate method is

shown in figure 2-5, view C.

For nonwatertight cables entering open

equipment, use the methods as shown in figure 2-5,

Figure 2-3.--Cable stripper.

views D and E.

2-8