equipment in which electrical clearances would be

reduced below minimum standards require solder

terminals.

For connection under a screwhead where a

standard terminal is not practicable, you can

use an alternate method. Bare the conductor for the

required distance and thoroughly clean the strands.

Then twist the strands tightly together, bend them

around a mandrel to form a suitable size loop (or

hook where the screw is not removable), and dip the

prepared end into solder. Remove the end, remove

the excess solder, and allow it to cool before connecting

it.

After the wiring installation has been completed,

measure the insulation resistance of the wiring

circuit with a Megger or similar (0- to 100-megohm,

500-volt dc) insulation resistance measuring

instrument. Do not energize a newly installed, repaired,

or modified wiring circuit without making sure (by

insulation tests) that the circuit is free of short circuits

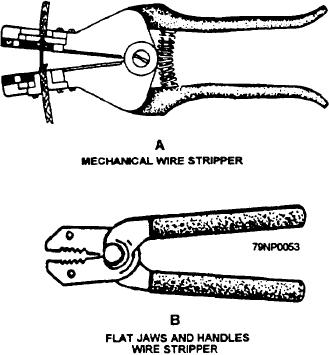

Figure 2-6.--Wire strippers.

and grounds.

Small refrigerators, drinking fountains, and

coffee makers are plugged into receptacles

Conductor Ends

connected directly to the ship's wiring. To

remove stress from the equipment terminal

Wire strippers (fig. 2-6) are used to strip insulation

block and its connected wiring, rigidly clamp

from the conductors. You must be careful not to nick

the cable to the frame of the equipment close

the conductor stranding while removing the insulation.

Do not use side or diagonal cutters for stripping

to the point where the cable enters the equip-

insulation from conductors.

ment.

Thoroughly clean conductor surfaces before

applying the terminals. After baring the conductor

Conductor Identification

end for a length equal to the length of the terminal

barrel, clean the individual strands thoroughly

Each terminal and connection of rotating ac and dc

and twist them tightly together. Solder them to form a

equipment, controllers, and transformers is marked with

neat, solid terminal for fitting either approved clamp

standard designations. This is done with synthetic resin

lugs or solder terminals. If the solder terminal is

tubing or fiber wire markers located as close as

used, tin the terminal barrel and clamp it tightly over

the prepared conductor (before soldering) to

practicable to equipment terminals, with fiber tags near

provide a solid mechanical joint. You do not need to

the end of each conductor, or with a stamp on the

solder conductor ends for use with solderless

terminals.

terminals applied with a crimping tool. Don't use

a side or diagonal cutter for crimping solderless

Individual conductors may also be identified

terminals.

by a system of color coding. Color coding

of individual conductors in multi conductor

Solderless terminals may be used for lighting,

cable is done according to the color coding tables

power, interior communications, and fire control

contained in Naval Ships' Technical Manual, Chapter

applications. However, equipment provided with solder

320.

terminals by the manufacturer and wiring boxes or

2-11