insulation limiting temperature and the sum of the

Class T insulation. Class T insulation is a silicone

ambient and temperature rise temperatures is the

rubber treated glass tape. It is also used in

additional temperature allowed for the hot-spot

reduced-diameter cables in sizes 14 through 2000.

temperature.

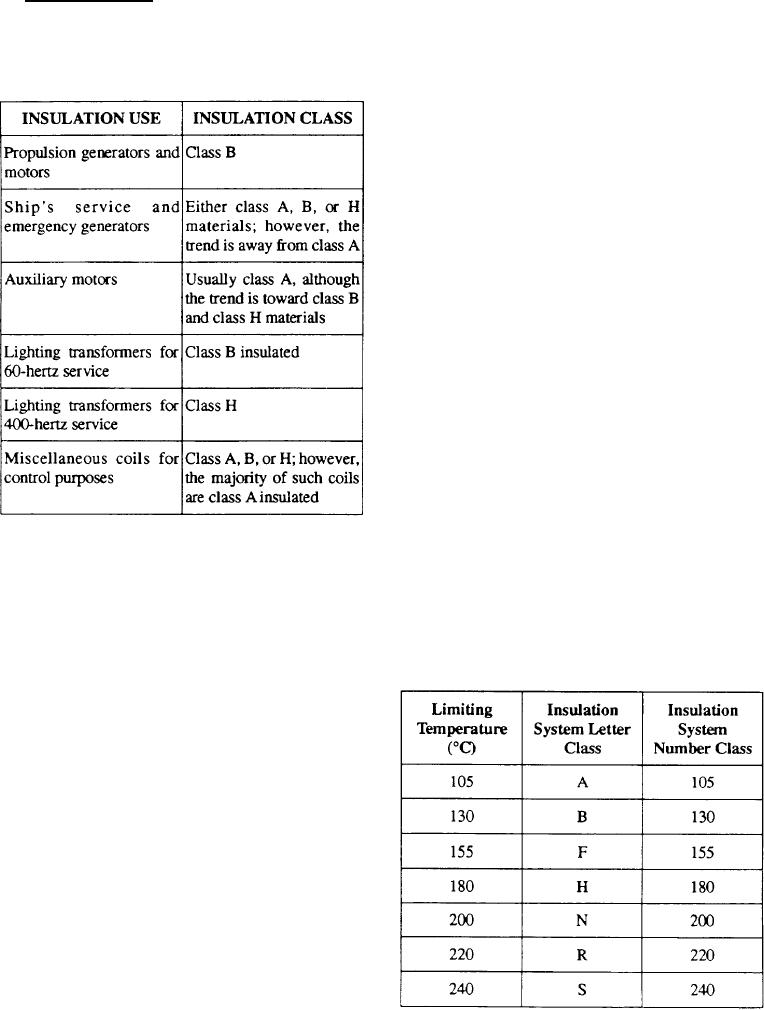

For an idea of some insulation uses, look at the table

The ultimate temperature rise of electrical

shown below:

equipment is reached when the rate at which heat is

developed equals the rate at which heat is transferred to

the surrounding atmosphere. The heat developed by

electrical equipment can usually be accurately

measured. However, the temperature of the immediate

surrounding area (ambient temperature) can become

critical to the equipment if proper ventilation is not

maintained.

The maximum allowable temperature rise and the

design ambient temperature allowed for electrical

equipment are usually shown on equipment nameplates,

on equipment drawings, and in technical manuals for

specific equipment. When information is not available

from these sources, refer to NSTM, chapter 300, for

information on the maximum permissible temperature

rises.

The engineering design of ships takes into account

the relationship of cable sizes and resistances with the

cable load currents and temperatures.

Insulation Resistance Measurements.

Temperature Effects on Insulation.

The insulation resistance of shipboard electrical

Very high temperatures that produce actual burning

cable must be measured periodically with an

or charring may destroy insulation in a few seconds. It

insulation-resistance-measuring instrument (Megger)

is important to maintain operating temperatures of

to determine the condition of the cable. Measurements

electrical equipment within their designed values to

avoid premature failure of insulation Temperatures

Table 2-6.--Limiting Temperature of Insulation systems

only slightly in excess of designed values may produce

gradual deterioration, which, though not immediately

apparent, shortens the life of the insulation. As a rule of

thumb, thermal aging will cause the life of insulation

will decrease by 1/2 for every 10 to 15C increase in

the operating temperature above the rated temperature

for the insulation class.

Insulation system classes are designated by letters,

numbers, or other symbols and may be defined as

assemblies of insulation materials in association with

equipment parts. Table 2-6 shows the insulation system

classification used for Navy electrical equipment based

on limiting temperatures. The limiting temperatures of

an insulation system may be established by test or by

service, and depend on an observable temperature rise

of the equipment, design ambient temperature, and

hot-spot temperature. The difference between the

2-16