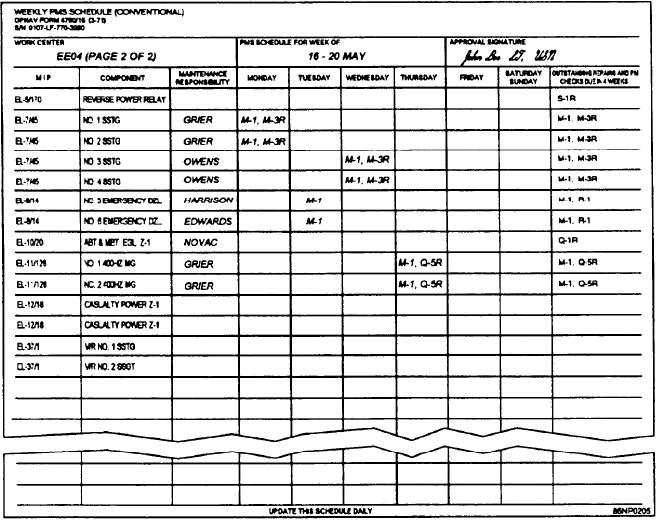

The Weekly PMS Schedule contains blank spaces

of maintenance requirements on a weekly basis

for the following information: work center code, date of

throughout the quarter. There are also columns to enter

current week, division officer's signature, MIP number

the MIP number and PMS requirements that may

minus the date code, component names, names of

require rescheduling. There are "tick" marks across the

personnel responsible for specific maintenance items,

top of the scheduling columns for use in showing the

periodicity codes of maintenance requirements,

in-port/underway time of the ship for the quarter.

outstanding major repairs, and situation requirements.

The engineering officer must supervise scheduling

of PMS on the quarterly schedule for his/her

The workcenter supervisor is responsible for

department, then sign and date the schedule before it is

completing the Weekly PMS Schedule and for updating

posted. At the end of each quarter, the engineer officer

it every day.

must review the quarterly schedule, check the reasons

for PMS actions not accomplished, and sign the form in

SCHEDULING WORK

the space provided on its reverse side. The division

Careful planning is required to keep up with all

officer is responsible for updating the quarterly schedule

maintenance and repair work within your division. You

every week. Completed quarterly schedules should be

should already have in your workcenter the following

kept on file for 1 year.

documents to help you schedule your work:

Weekly Schedule

The Current

MaintenanceProject

Ship's

The Weekly PMS Schedule (fig. 13-12) is a visual

(CSMP)

display of the planned maintenance scheduled for

The Job Control Number (JCN) Log

accomplishment in a given workcenter during a specific

week. The weekly schedule is used by the workcenter

The Quarterly PMS Schedule

supervisor to assign and monitor the accomplishment of

The Weekly schedule

required PMS tasks by workcenter personnel.

Figure 13-12.--Weekly PMS Schedule.

13-17